Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Analysis of the market structure of long-distance transport vehicles in the context of retrofitting diesel engines with modern dual-fuel systems.

1

Department of Engines and Maintenance

Engineering, Faculty of Mechanical Engineering, Military University of Technology, Poland

Submission date: 2021-07-15

Final revision date: 2021-09-08

Acceptance date: 2021-09-12

Online publication date: 2021-09-15

Publication date: 2022-02-01

Corresponding author

Janusz Chojnowski

Department of Engines and Maintenance Engineering, Faculty of Mechanical Engineering, Military University of Technology, gen. Sylwestra Kaliskiego 2, 00-908, Warsaw, Poland

Department of Engines and Maintenance Engineering, Faculty of Mechanical Engineering, Military University of Technology, gen. Sylwestra Kaliskiego 2, 00-908, Warsaw, Poland

Combustion Engines 2022,188(1), 13-17

KEYWORDS

TOPICS

ABSTRACT

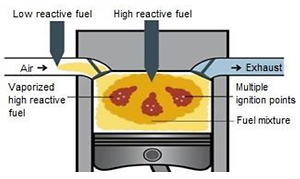

The demands placed on vehicles are constantly increasing. European legislation has forced commercial vehicle manufacturers to develop ever more powerful and dynamic engines with low fuel consumption. With the appearance of exhaust gas standards, truck manufacturers realized that it was necessary to improve the fuel supply system so that the combustion process was more efficient. To achieve this the fuel injected into the cylinders had to be finer in order to mix more easily with air. High-pressure unit injection systems have proved to be a good and reliable solution. They are also relatively cheap to produce and less prone to fuel contamination. Many years and millions of failure-free kilometers traveled on unit injectors effectively distracted some users and producers from the Common Rail system. Exhaust gas standards and increasing consumer expectations forced manufacturers to take another step in their development, i.e. the need for more precise fuel injection control. The injectors had to run faster in order to carry out the initiation dose, the actual injection and the extra injection. All these modifications make diesel engines in commercial vehicles such as tractor units much more powerful. They also allow for cooperation with aftermarket dual-fuel CNG-ON and LPG-ON installations. Dual-fuel solutions are perhaps another step towards reducing emissions, and thanks to reduced tolls, they are becoming a real alternative to conventional fuel-powered tractor units. This work focuses on the structure of the truck tractor market in terms of selecting cars used for the use of a non-factory dual-fuel CNG-ON installation.

REFERENCES (21)

1.

GARCIA, A., CARLUCCI, P., MONSALVE-SERRANO, J. et al. Energy management optimization for a power-split hybrid in a dual-mode RCCI-CDC engine. Applied Energy. 2021, 302, 117525. https://doi.org/10.1016/j.apen....

2.

HEYWOOD, J.B, Internal Combustion Engine Fundamentals. Second Edition. McGraw-Hill Education. New York 2018. https://www.accessengineeringl....

3.

KOŹLAK, A. Struktura sektora transportu drogowego w Polsce i ocena jego wyników ekonomicznych na tle państw, Unii Europejskiej. Studia i Prace Kolegium Zarządzania i Finansów. 2018, 166, 59-75. https://econjournals.sgh.waw.p....

4.

URBANYI-POPIOŁEK, I. Ekonomiczne i organizacyjne aspekty transportu. Wyższa Szkoła Gospodarki w Bydgoszczy. Bydgoszcz 2019.

5.

REPORT of the Polish Central Statistical Office: GUS- Transport: wyniki działalności 2019.

6.

REPORT of the Polish Automotive Industry Association: PZPM – Branża motoryzacyjna, raport 2020/2021.

8.

Data from diagnostic programs: TEXA Truck version 51.0.0 IDC5 (2021) and Bosch ESI [tronic] 2.0 Truck (2021).

18.

Arena Red. Engine Management Systems. https://www.arenared.nl/cpbc+~... (accessed on 27 08 2021).

CITATIONS (4):

1.

Experimental Assessment of the Impact of Replacing Diesel Fuel with CNG on the Concentration of Harmful Substances in Exhaust Gases in a Dual Fuel Diesel Engine

Mirosław Karczewski, Grzegorz Szamrej, Janusz Chojnowski

Energies

Mirosław Karczewski, Grzegorz Szamrej, Janusz Chojnowski

Energies

2.

Preliminary tests of a Diesel engine powered by diesel and hydrogen

Rafał Longwic, Dawid Tatarynow, Michal Kuszneruk, Gracjana Wozniak-Borawska

Combustion Engines

Rafał Longwic, Dawid Tatarynow, Michal Kuszneruk, Gracjana Wozniak-Borawska

Combustion Engines

3.

Prospects for the development of drivetrain systems in trucks

Grzegorz Kubica, Stefan Lageweg

Combustion Engines

Grzegorz Kubica, Stefan Lageweg

Combustion Engines

4.

Emission control and carbon capture from diesel generators and engines: A decade-long perspective

Shervan Babamohammadi, Amy R Birss, Hamid Pouran, Jagroop Pandhal, Tohid N. Borhani

Carbon Capture Science & Technology

Shervan Babamohammadi, Amy R Birss, Hamid Pouran, Jagroop Pandhal, Tohid N. Borhani

Carbon Capture Science & Technology

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.