Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Comparison of the strength of popular thermoplastic materials used in 3D printing - PLA, ABS and PET-G

1

Politechnika Śląska, Wydział Matematyki Stosowanej, Poland

2

Wydział Organizacji i Zarządzania, Politechnika Śląska, Poland

Submission date: 2023-11-30

Final revision date: 2024-04-17

Acceptance date: 2024-05-27

Online publication date: 2024-07-19

Publication date: 2024-11-13

Corresponding author

Beniamin Stecuła

Politechnika Śląska, Wydział Matematyki Stosowanej, Kaszubska 23, 44-100, Gliwice, Poland

Politechnika Śląska, Wydział Matematyki Stosowanej, Kaszubska 23, 44-100, Gliwice, Poland

Combustion Engines 2024,199(4), 97-103

KEYWORDS

TOPICS

ABSTRACT

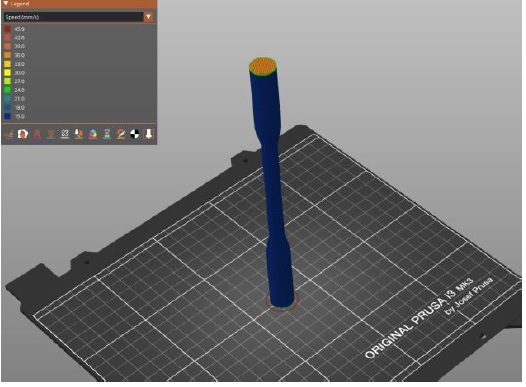

This paper presents the results of a comparative analysis of three prevalent materials used in 3D printing. PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), and PET-G (Polyethylene Terephthalate Glycol). The study includes strength testing using a tensile testing machine. Beginning with the selection of the input material used in 3D printing process, the research aimed to provide insights into the strength properties of these materials. Autodesk Fusion 360 software was used for the precise design of the 3D model, ensuring suitability for subsequent tensile testing. The physical samples were then printed using 3D printing technology. The samples were subjected to a strength examination using a tensile testing machine. The data collection phase recorded and compiled the results of each strength test, forming the foundation for a comprehensive analysis. Using statistical methods and comparative analyzes, the data were thoroughly examined, allowing the derivation of conclusive observations and insights into the comparative strengths of PLA, ABS, and PET-G. The findings not only contribute to a deeper understanding of material performance, but also provide a guide for material selection in 3D printing applications, guiding future research endeavors and industry applications in the ever-evolving landscape of additive manufacturing.

REFERENCES (40)

1.

Asadollahi-Yazdi E, Couzon P, Nguyen NQ, Ouazene Y, Yalaoui F. Industry 4.0: Revolution or evolution? Am J Oper Res. 2020;10(6):241. https://doi.org/10.4236/ajor.2....

2.

Banaeian Far S, Imani Rad A, Hosseini Bamakan SM, Ra-jabzadeh Asaar M. Toward metaverse of everything: oppor-tunities, challenges, and future directions of the next genera-tion of visual/virtual communications. J Netw Comput Appl. 2023;217:103675. https://doi.org/10.1016/j.jnca....

3.

Belloncle B, Bunel C, Menu-Bouaouiche L, Lesouhaitier O, Burel F. Study of the degradation of poly(ethyl glyoxylate): biodegradation, toxicity and ecotoxicity assays. J Polym En-viron. 2012;20:726-731. https://doi.org/10.1007/s10924....

5.

Dolan R, Budde R, Schramm C, Rezaei R. 3D printed piston for heavy-duty diesel engines. Proc. of the 2018 Ground Vehicle Systems Engineering and Technology Symposium. 2018. https://events.esd.org/wp-cont....

6.

Grefen B, Becker J, Linke S, Stoll E. Design, production and evaluation of 3d-printed mold geometries for a hybrid rocket engine. Aerospace, 2021;8(8):220. https://doi.org/10.3390/aerosp....

7.

Guessasma S, Belhabib S, Nouri H. Printability and tensile performance of 3D printed polyethylene terephthalate glycol using fused deposition modelling. Polymers. 2019;11(7):1220. https://doi.org/10.3390/polym1....

8.

Gupta S, Kar AK, Baabdullah A, Al-Khowaiter WAA. Big data with cognitive computing: a review for the future. Int J Inf Manage. 2018;42:78-89. https://doi.org/10.1016/j.ijin....

9.

Gwiazda P. Praca z filamentem – najczęściej zadawane pytania (in Polish). https://centrumdruku3d.pl/prac... (accessed on 2023-11-20).

10.

Ilyas R, Zuhri M, Aisyah H, Asyraf M, Hassan S, Zainudin E et al. Natural fiber-reinforced polylactic acid, polylactic acid blends and their composites for advanced applications. Polymers. 2022;14(1):202. https://doi.org/10.3390/polym1....

11.

Liaw C-Y, Guvendiren M. Current and emerging applications of 3D printing in medicine. Biofabrication. 2017;9(2):24102. https://doi.org/10.1088/1758-5....

12.

Luning-Prak D, Baker B, Cowart J. Engine o-rings produced using additive manufacturing. SAE Technical Paper 2023-01-0893. 2023. https://doi.org/10.4271/2023-0....

13.

Marciniak D, Szewczykowski P, Czyżewski P, Sykutera D, Bieliński M. Effect of surface modification by acetone va-porization on the structure of 3D printed acrylonitrilebutadi-ene-styrene elements. Polimery. 2018;63(11-12):785-790. https://doi.org/10.14314/polim....

17.

Mehmood M, Li J, Jaffri Z, Hassan M. Performance evalua-tion of ABS (acrylonitrile-butadiene styrene) as high voltage insulator in the outdoor environment. 2017 1st International Conference on Electrical Materials and Power Equipment (ICEMPE), 2017:700-702. https://doi.org/10.1109/ICEMPE....

18.

Mitra S, de Castro AR, El Mansori M. On the rapid manu-facturing process of functional 3D printed sand molds. J Manuf Process. 2019;42:202-212. https://doi.org/10.1016/j.jmap....

19.

Mohanavel V, Priyadharshan R, Ravichandran M, Sivanraju R, Velmurugan P, Subbiah R. The role and application of 3D printer in the automobile industry. ECS Trans. 2022;107(1):12001. https://doi.org/10.1149/10701.....

20.

Murariu M, Dubois P. PLA composites: from production to properties.. Adv Drug Deliver Rev. 2016;107:17-46. https://doi.org/10.1016/j.addr....

21.

Nofar M, Saçlıgil D, Carreau P, Kamal M, Heuzey M. Poly (lactic acid) blends: processing, properties and applications. Int J Biol Macromol. 2019;125:307-360. https://doi.org/10.1016/j.ijbi....

22.

Olivera S, Muralidhara H, Venkatesh K., Gopalakrishna K, Vivek C. Plating on acrylonitrile–butadiene–styrene (ABS) plastic: a review. J Mater Sci. 2016;51:3657-3674. https://doi.org/10.1007/s10853....

23.

Orzeł B, Stecuła K. Comparison of 3D printout quality from FDM and MSLA technology in unit production. Symmetry. 2022;14(5):910. https://doi.org/10.3390/sym140....

24.

Pogodin VA, Rabinskii LN, Sitnikov SA. 3D printing of components for the gas-discharge chamber of electric rocket engines. Russ Engin Res. 2019;39:797-799. https://doi.org/10.3103/S10687....

27.

Sadeeq MM, Abdulkareem NM, Zeebaree SRM, Ahmed DM, Sami AS, Zebari RR. IoT and cloud computing issues, challenges and opportunities: a review. Qubahan Acad J. 2021;1(2):1-7. https://doi.org/10.48161/qaj.v....

28.

Satsangi R, Singh H, Satsangee GR, Agrawal S, Sharma S, Gautam G. The concept of viscous material (chocolate) 3D printer/food 3D printer. International Research Journal of Engineering and Technology. 2018;5(2):2144-2148. https://api.semanticscholar.or....

29.

Sava M, Nagy R, Menyhardt K. Characteristics of 3D print-able bronze PLA-based filament composites for gaskets. Materials. 2021;14(16):4770. https://doi.org/10.3390/ma1416....

30.

Shaikh S, Jadhav H, Gajinkar A, Khare I, Singh M. Selection of additive manufacturing technology for optimized intake manifold: a review. PalArch's Journal of Archaeology of Egypt/Egyptology. 2020;17(9):4270-4300. https://archives.palarch.nl/in....

31.

Stępień Z. Analysis of the prospects for hydrogen-fuelled internal combustion engines. Combustion Engines. 2024;197(2):32-41. https://doi.org/10.19206/CE-17....

32.

Szczepański E, Jachimowski R, Rudyk T. Simulation studies of fleet vehicle selection in terms of pollutant emissions. Combustion Engines. 2024;196(1):80-88. https://doi.org/10.19206/CE-16....

33.

Tomaszewski S, Grygier D, Dziubek M. Assessment of engine valve materials. Combustion Engines. 2023;194(3):48-51. https://doi.org/10.19206/CE-16....

34.

Valvez S, Silva A, Reis P. Optimization of Printing Parame-ters to maximize the mechanical properties of 3D-printed PETG-based parts. Polymers, 2022, 14(13):2564. https://doi.org/10.3390/polym1....

35.

Woo I, Kim D, Kang H, Lyu M. Cross-section morphology and surface roughness of an article manufactured by material extrusion-type 3D printing according to the thermal con-ductivity of the material. Elastomers and Composites. 2020;55:46-50. https://doi.org/10.7473/EC.202....

36.

Xiao J, Ji G, Zhang Y, Ma G, Mechtcherine V, Pan J et al. Large-scale 3D printing concrete technology: current status and future opportunities. Cem Concr Compos. 2021;122:104115. https://doi.org/10.1016/j.cemc....

37.

Zhang X, Xia M, Su X, Yuan P, Li X, Zhou C et al. Photo-lytic degradation elevated the toxicity of polylactic acid mi-croplastics to developing zebrafish by triggering mitochon-drial dysfunction and apoptosis. J Hazard Mater. 2021;413:125321. https://doi.org/10.1016/j.jhaz....

CITATIONS (3):

1.

Assessment of physio-mechanical characteristics of ABS/PETG blended parts fabricated by material extrusion 3D printing

Vishal Mishra, Nikhil Bharat, Vijay Kumar, Dhinakaran Veeman, Murugan Vellaisamy

Physica Scripta

Vishal Mishra, Nikhil Bharat, Vijay Kumar, Dhinakaran Veeman, Murugan Vellaisamy

Physica Scripta

2.

Enhanced Tensile Strength and Fracture Toughness of 3D Printed PETG/ABS Blend for Load-Bearing Application

Vishal Mishra, Dhinakaran Veeman, Sushant Negi

Journal of Materials Engineering and Performance

Vishal Mishra, Dhinakaran Veeman, Sushant Negi

Journal of Materials Engineering and Performance

3.

A COMPARATIVE STUDY ON THE TENSILE PROPERTIES OF PLA, PETG, AND ABS IN FDM 3D PRINTING: EFFECTS OF INFILL GEOMETRY AND BUILD ORIENTATION

Mehmet Albaşkara, İsmail Yıldız

International Journal of 3D Printing Technologies and Digital Industry

Mehmet Albaşkara, İsmail Yıldız

International Journal of 3D Printing Technologies and Digital Industry

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.