Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Crankshaft geometry modification and strength simulations for a new design of diesel opposed-piston engine

1

Faculty of Mechanical Engineering, Department of Thermodynamics, Fluid Mechanics and Aviation Propulsion Systems, Lublin University of Technology, Poland

Submission date: 2023-05-31

Final revision date: 2023-07-03

Acceptance date: 2023-07-07

Online publication date: 2023-08-08

Publication date: 2023-09-15

Corresponding author

Paweł Magryta

Faculty of Mechanical Engineering, Department of Thermodynamics, Fluid Mechanics and Aviation Propulsion Systems, Lublin University of Technology, ul. Nadbystrzycka 36 / 710, 20-618, Lublin, Poland

Faculty of Mechanical Engineering, Department of Thermodynamics, Fluid Mechanics and Aviation Propulsion Systems, Lublin University of Technology, ul. Nadbystrzycka 36 / 710, 20-618, Lublin, Poland

Combustion Engines 2023,194(3), 123-128

KEYWORDS

TOPICS

ABSTRACT

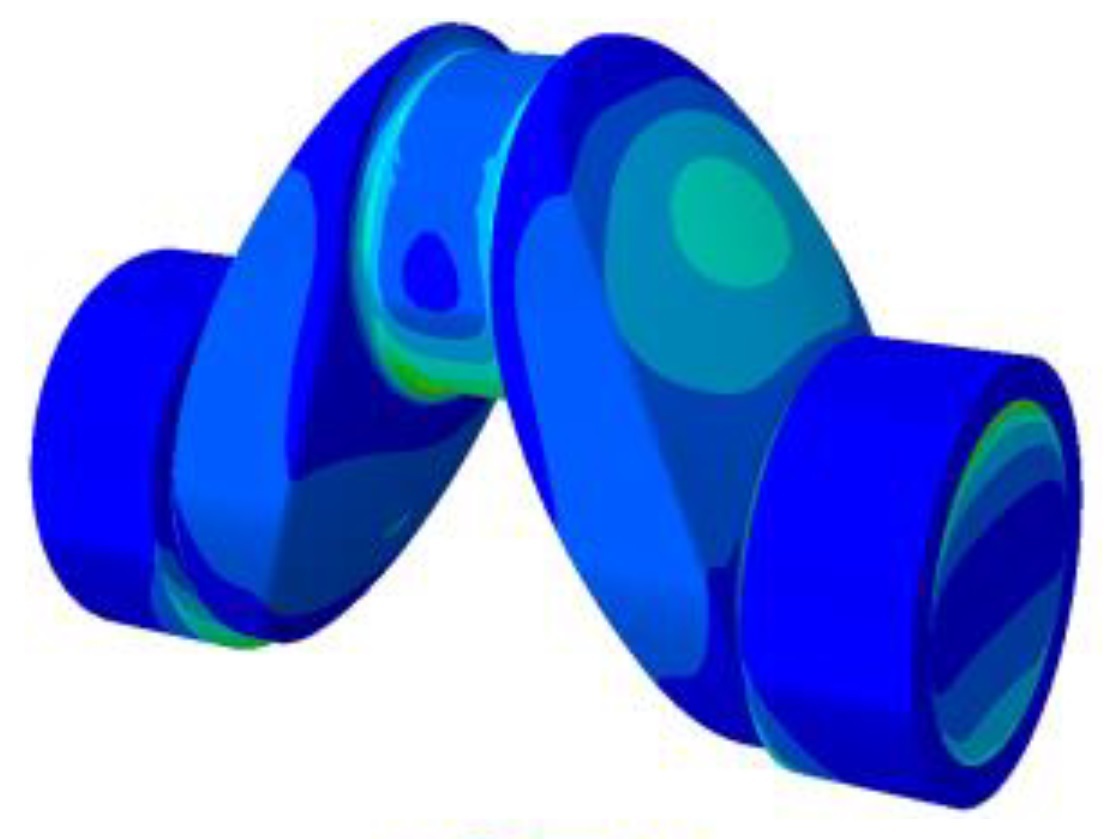

The article presents simulation strength calculations of a newly designed crankshaft for a PZL 100 engine with a reciprocating piston design. This engine is the subject of a research and development project co-financed by NCBR. The article presents four successive versions of the crankshaft geometric changes which underwent strength calculations. Such elements as the outer and inner parts of the crankshaft arm were changed in these geometric versions. The geometry of the shaft was changed using Catia v5 software, while strength calculations were carried out in Abaqus software. In summary, one of the presented models was selected for further work due to the possible simplification of the manufacturing process and the reduction of mass and stresses. This model was further investigated in the project.

REFERENCES (23)

1.

Anderson T. Superior’s New Gemini Diesel (posted on 28.06.2015). http://www.dieselarmy.com/news....

2.

Ang YZ, Ku PX. Study on failure analysis of crankshaft using finite element analysis. MATEC Web Conf. 2021;335:03001. https://doi.org/10.1051/matecc....

3.

Bulut M, Cihan O, Temizer I. Fatigue life and stress analysis of the crankshaft of a single cylinder diesel engine under variable forces and speeds. Mater Test. 2021;63(8):770-777. https://doi.org/10.1515/mt-202....

4.

Chien WY, Pan J, Close D, Ho S. Fatigue analysis of crankshaft sections under bending with consideration of residual stresses. Int J Fatigue. 2005;1(27):1-19. https://doi.org/10.1016/j.ijfa....

5.

Choi KS, Pan J. Simulations of stress distributions in crankshaft sections under fillet rolling and bending fatigue tests. Int J Fatigue. 2009.31(3):544-557. https://doi.org/10.1016/j.ijfa....

6.

Flint M, Pirault J-P. Opposed piston engines: evolution, use, and future applications. SAE International 2009.

7.

Gęca M, Czyz Z, Sułek M. Diesel engine for aircraft propulsion system. Combustion Engines. 2017;169(2):7-13. https://doi.org/10.19206/CE-20....

8.

Grabowski Ł, Pietrykowski K, Karpiński P. FEM simulation research of natural frequency vibration of crankshaft from internal combustion engine. ITM Web Conf. 2017;15:07004. https://doi.org/10.1051/itmcon....

9.

Grabowski Ł, Pietrykowski K, Karpiński P. The zero-dimensional model of the scavenging process in the opposed-piston two-stroke aircraft diesel engine. Propulsion and Power Research. 2019;8(4):300-309. https://doi.org/10.1016/j.jppr....

10.

He CM, Xu SC. Opposed-piston crankshaft system dynamics simulation and durability analysis in a neotype two-stroke diesel engine. American Journal of Mechanical and Industrial Engineering. 2017;2(2):54-63 https://doi.org/10.11648/j.ajm....

11.

Karthick L, Stephen Leon J, Ravi R, Michel J, Mallireddy N, Vadivukarasi L. Modelling and analysis of an EN8 crankshaft in comparison with AISI 4130 crankshaft material. Mater Today-Proc. 2022;52(3):1036-1040. https://doi.org/10.1016/j.matp....

12.

Montazersadgh FH, Fatemi A. Dynamic load and stress analysis of a crankshaft. SAE Technical Paper 2007-01-0258. 2007. https://doi.org/10.4271/2007-0....

13.

Montazersadgh FH, Fatemi A. Stress analysis and optimization of crankshafts subject to dynamic loading. A Final Project Report Submitted to the Forging Industry Educational Research Foundation (FIERF) and American Iron and Steel Institute (AISI). 2007.

14.

Mosakowski R. Analysis of balancing of six-cylinder in-line two-stroke internal combustion engines. Combustion Engines. 2009;139(4):22-33. https://doi.org/10.19206/CE-11....

15.

Naik S, Johnson D, Fromm L, Koszewnik J, Redon F, Regner G et al. Achieving Bharat Stage VI emissions regulations while improving fuel economy with the opposed-piston engine. SAE Int J Engines. 2017;10(1):17-26. https://doi.org/10.4271/2017-2....

16.

Opaliński M, Teodorczyk A, Kalke J. The closed-cycle model numerical analysis of the impact of crank mechanism design on engine efficiency. Combustion Engines. 2017;168(1):153-160. https://doi.org/10.19206/CE-20....

17.

Pietrykowski K, Magryta P, Skiba K. Finite element analysis of a composite piston for a diesel aircraft engine. Combustion Engines. 2019;179(4):107-111. https://doi.org/10.19206/CE-20....

18.

Regner G, Johnson D, Koszewnik J, Dion E, Redon F, Fromm L. Modernizing the opposed piston, two stroke engine for clean, efficient transportation. SAE Technical Paper 2013-26-0114. 2013. https://doi.org/10.4271/2013-2....

19.

Sandya K, Keerthi M, Srinivas K. Modeling and stress analysis of crankshaft using FEM package Ansys. International Research Journal of Engineering and Technology. 2016;3(1):687-693. https://www.irjet.net/archives....

20.

Shokrollahihassanbarough F. Alqahtani A, Wyszynski ML, Thermodynamic simulation comparison of opposed two-stroke and conventional four-stroke engines. Combustion Engines. 2015;162(3):78-84. https://doi.org/10.19206/CE-11....

21.

Thejasree P, Dileep Kumar G, Leela Prasanna Lakshmi S. Modelling and analysis of crankshaft for passenger car using ANSYS. Mater Today-Proc. 2017;4(10):11292-11299. https://doi.org/10.1016/j.matp....

22.

Vinay AV, Shankar MU, Satya LP, Kumar YS, Srikanth M. Modelling and analysis of crankshaft for four stroke diesel engine by using composite materials. Bachelor Thesis in Anil Neerukonda Institute of Technology and Sciences. India 2021.

23.

Witek L, Sikora M, Stachowicz F, Trzepiecinski T. Stress and failure analysis of the crankshaft of diesel engine. Eng Fail Anal. 2017;82:703-712. https://doi.org/10.1016/j.engf....

CITATIONS (1):

1.

Investigation of novel ceramic materials (Al2O3 and SSiC) for high-pressure pumps’ delivery sections

Marek Idzior, Wojciech Karpiuk, Rafal Smolec

Combustion Engines

Marek Idzior, Wojciech Karpiuk, Rafal Smolec

Combustion Engines

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.