Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Design of the turbocharger bearing arrangement to increase the overall efficiency of the combustion engine

1

Mechanical Engineering, Wroclaw University of Science and Technology, Poland

Submission date: 2021-07-27

Final revision date: 2021-09-16

Acceptance date: 2021-09-16

Online publication date: 2021-09-20

Publication date: 2022-02-01

Corresponding author

Zbigniew Jan SROKA

Mechanical Engineering, Wroclaw University of Science and Technology, wybrzeze Wyspianskeigo 27, PL-50-370, Wroclaw, Poland

Mechanical Engineering, Wroclaw University of Science and Technology, wybrzeze Wyspianskeigo 27, PL-50-370, Wroclaw, Poland

Combustion Engines 2022,188(1), 83-89

KEYWORDS

TOPICS

ABSTRACT

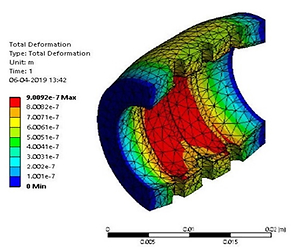

The main objective of this study was to design a journal bearing, such that it can withstand the forces that arise in context to increasing the length of the shaft in an automotive turbocharger. The work will also provide information on how the design changes affect the overall performance of the bearing. The design changes include the thickness of the oil film, the number of grooves, the dimension of the grooves, the number of inlets and outlets, the dimension of the babbitt and mainly the length of the journal bearing. The simulation models were created using CATIA V5 and the analysis is done using ANSYS 19.2. The flow is considered to be laminar and is calculated using Reynold’s Equation. The new concept gave insight on how the design considerations affect the pressure distribution and the pressure developed. From the results, it was interpreted that the new design can withstand the four times the pressure while distributing the pressure over twice the original design.

REFERENCES (24)

3.

BOMPOS, D.A., NIKOLAKOPOULOS, P.G. Tribological design of a multistep journal bearing. Simulation Modelling Practice and Theory. 2016, 68, 18-32. https://doi.org/10.1016/j.simp....

4.

CAMPO E.A. Plastic journal bearing design. The Complete Part Design Handbook, 2006, 335–376.

5.

CHEN, W.J. Rotordynamics and bearing design of turbochargers. Mechanical Systems and Signal Processing. 2012, 29, 77-89. https://doi.10.1016/j.ymssp.20....

6.

CHUEPENG, S., SAIPOM, S. Lubricant thermo-viscosity effects on turbocharger performance at low engine load. Applied Thermal Engineering. 2018, 139, 334-340. https://doi.org/10.1016/j.appl....

7.

CYPKO, E., KALDONSKI, T. Influence of lubricated sliding couple structural material type on generated potential difference value. Journal of KONES Powertrain and Transport. 2011, 18(1).

8.

DOWSON, D., TAYLOR, C.M., GODET, M. et al. Fluid film lubrication – Osborne Reynolds centenary. Proceedings of 13th Leeds-Lyon Symposium on Tribology. 1986, 11. University of Leeds, England.

9.

KALDONSKI, T. Fundamentals of analysing od tribological processes. WAT Publisher, Warsaw 2015 (in Polish).

10.

KOUTSOVASILIS, P., DRIOT, N., DAIXING, L. et al. Quantification of sub-synchronous vibrations for turbocharger rotors with full-floating ring bearings. Archive Applied Mechanics. 2015, 85(4), 481-502. https://doi.org/10.1007/s00419....

11.

LAWROWSKI, Z. Tribology. friction, wear and lubrication. PWN Publisher. Warsaw 1993 (in Polish).

12.

LI, C., WANG, Y., JIA, B. et al. Application of Miller cycle with turbocharger and ethanol to reduce NOx and particulates emissions from diesel engine – a numerical approach with model validations. Applied Thermal Engineering. 2019, 150, 904-911. https://doi.org/10.1016/j.appl....

13.

MANSHOOR, B., JAAT, M., IZZUDDIN, Z. et al. CFD analysis of thin film lubricated journal bearing. Procedia Engineering. 2013, 68, 56-62. https://doi.org/10.1016/j.proe....

14.

NICHOLAS, J., ALLAIRE, P., LEWIS, D. Stiffness and damping coefficients for finite length step journal bearings. ASLE Transactions. 2008, 23(4), 353-362. https://doi.org/10.1080/056981....

15.

ROMAGNOLI, A., MANIVANNAN, A., RAJOO, S. et al. A review of heat transfer in turbochargers. Renewable and Sustainable Energy Reviews. 2017, 79, 1442-1460. https://doi.org/10.1016/j.rser....

16.

ROY L., LAHA, S. Steady state and dynamic characteristics of axial grooved journal bearings. Tribology International. 2009, 42(5), 754-761, https://doi.org/10.1016/j.trib....

17.

SCOTT, R. Journal bearings and their lubrication. Machinery Lubrication. Publish by Noria. 2005, 7, https://www.machinerylubricati....

18.

SCHWARZ, J.B., ANDREWS, D.N. Considerations for gas stand measurement of turbocharger performance. Proceedings 11th International Conference on Turbochargers and Turbocharging. 2014, 253-264. Institute of Mechanical Engineers, London.

19.

SEP, J., TOMCZEWSKI, L., GALDA, L. et al. The study on abrasive wear of grooved journal bearings. Wear. 2017, 376-377, 54-62. https://doi.org/10.1016/j.wear....

20.

SHAABAN, S., SEUME, J. Impact of turbocharger non-adiabatic operation on engine volumetric efficiency and turbo lag. International Journal of Rotating Machinery. 2011, 2012. https://doi.org/10.1155/2012/6....

21.

SJOBERG, E. Friction characterization of turbocharger bearings. Master of Science Thesis MMK. 2013, 149.

22.

STAHL, J., JACOBSON, B.O. Design function for hydrodynamics bearings. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology. 2001, 215(5), 405-416. https://doi.org/10.1243/135065....

23.

SUMMER, F., GRÜN, F., OFFENBECHER, M. et al. Challenges of friction reduction of engine plain bearings – tackling the problem with novel bearing materials. Tribology International. 2018, 131, 238-250. https://doi:10.1016/j.triboint....

24.

VANHAELST, R., KHEIR, A., CZAJKA, J. A systematic analysis of the friction losses on bearings of modern turbocharger. Combustion Engines. 2016, 164(1), 22-31. https://doi.org/10.19206/CE-11....

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.