Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

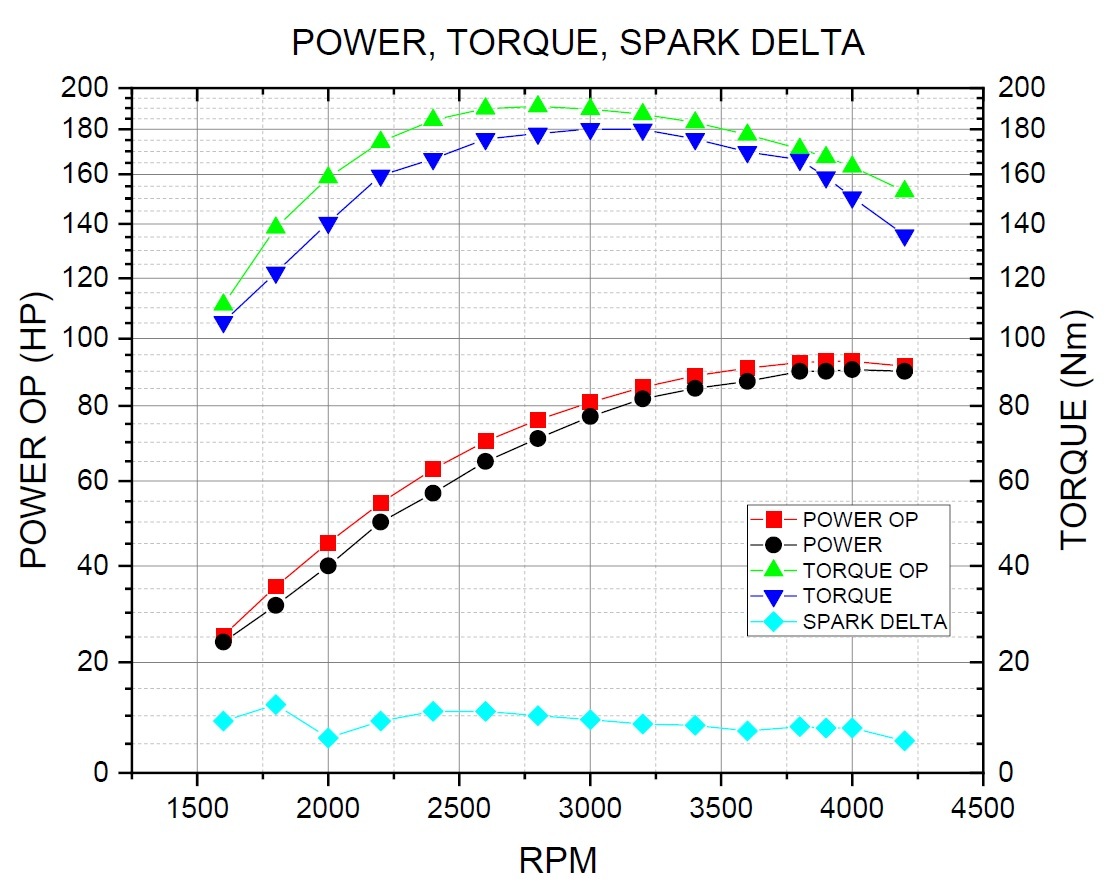

Efficiency optimization of a vehicle combustion engine by the adjustment of the spark advance angle

1

Vehicle Engineering, Wrocław University of Science and Technology, Poland

Submission date: 2023-05-31

Final revision date: 2023-10-27

Acceptance date: 2023-11-10

Online publication date: 2023-12-16

Publication date: 2024-01-02

Corresponding author

Combustion Engines 2024,196(1), 10-14

KEYWORDS

TOPICS

ABSTRACT

Changing the ignition advance angle has a significant impact on the performance of a

combustion engine. Optimization of ignition advance angle is a major task of adjusting engine

concerning emission standards, fuel consumption, torque value, etc. The results of the

research showed that the process of optimizing ignition advance curve can noticeably

increase engine efficiency, as well as torque and power output from the engine, while

reducing fuel consumption as a result of lower indications of the air flow mass per second

from MAF sensor (mass air flow sensor). The highest impact of the ignition advanced angle

modifications can be seen in the area of the highest volumetric efficiency of the tested

combustion engine. Almost no impact is observed within high engine speed levels.

Simultaneously increasing engine load and rotation speed increases the possibility of engine

knocking, which has devastating effect on engine durability.

REFERENCES (13)

1.

Ehsan M. Effect of spark advance on a gas run automotive spark ignition engine. J Chem Eng. 2010;1:42-49. https://doi.org/10.3329/jce.v2....

2.

El-Sharkawy MR, Abaskharon MBR, Abd-El-Tawwab AM, Ezzat Fawzy MH. Effect of static spark timing on the performance and emissions of a spark ignition engine using CNG. IOP Conf Ser Mater Sci Eng. 2019;518(3):12. https://doi.org/10.1088/1757-8....

3.

General D. Internal FOR. Comparative study on the differences between the EU and US legislation on emissions in the automotive sector. Inst Eur Environ Policy. 2015;53(9):1689-1699. https://doi.org/10.2861/503165.

4.

Hristov R, Bogdanov K, Dimitrov R. Research the influence of spark plugs types on the performance of the engine operating on gaseous fuels. Mobility & Vehicle Mechanics. 2018;44(1):51-61. https://doi.org/10.24874/mvm.2....

5.

Ibrahim A, Bari S. A comparison between EGR and lean-burn strategies employed in a natural gas SI engine using a two-zone combustion model. Energy Convers Manage. 2009;50(12):3129-3139. https://doi.org/10.1016/j.enco....

6.

Joshi A, Borse S. Study of the effect of spark advance, engine speed variation and number of spark plugs on engine performance using CFD software. Journal of Ocean, Mechanical and Aerospace. 2017;48(48):1-9. https://doi.org/10.36842/jomas....

7.

Lungu J, Siwale L, Luwaya E. Study and effect of ignition timing on the combustion characteristics of gasoline En 91 in a spark ignition engine. NAER-V1. 2021;104-2. https://doi.org/10.9734/bpi/na....

8.

Marzec P. Tests of a SI engine powered by gaseous fuels blends of LPG + DME of various proportions with variable load. Combustion Engines. 2022;190(3):23-26. https://doi.org/10.19206/CE-14....

9.

Nawazish Mehdi S, Yousufuddin S. Effect of ignition timing, equivalence ratio, and compression ratio on the performance and emission characteristics of a variable compression ratio SI engine using ethanol-unleaded gasoline blends. International Journal of Engineering. 2008;21(1):97-106. https://www.ije.ir/article_716....

10.

Ramasamy D, Kadirgama K, Rahman M, Zainal Z. Analysis of compressed natural gas burn rate and flame propagation on a sub-compact vehicle engine. International Journal of Automotive and Mechanical Engineering. 2015;11(1):2405-2416. https://doi.org/10.15282/ijame....

11.

Tribbett EJ, Froehlich EM, Bayer L. Effects of ignition timing, equivalence ratio and compression ratio on RDH engine performance. 2002. https://api.semanticscholar.or....

12.

Tunka L, Polcar A. Effect of various ignition timings on combustion process and performance of gasoline engine. Acta Univ Agric Silvic Mendelianae Brun. 2017;65(2):545-554. https://doi.org/10.11118/actau....

13.

Zareei J, Kakaee AH. Study and the effects of ignition timing on gasoline engine performance and emissions. Eur Transp Res Rev. 2013;5(2):109-116. https://doi.org/10.1007/s12544....

CITATIONS (1):

1.

A Novel Formula for Calculating the Dynamic Torque of an Engine Based on Its Geometric Parameters and Static Measurements

Piotr Bera, Agata Drzewosz

Energies

Piotr Bera, Agata Drzewosz

Energies

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.