Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Improving heat transfer in an air-cooled engine by redesigning the fins

1

Faculty of Mechanical Engineering, Wroclaw University of Science and Technology, Poland

2

Department of Motor Vehicle Engineering, College of Engineering, Ethiopian Defence University, Ethiopia

Submission date: 2024-08-01

Final revision date: 2024-10-28

Acceptance date: 2024-10-30

Online publication date: 2024-11-06

Publication date: 2025-06-22

Corresponding author

Zbigniew Jan Sroka

Faculty of Mechanical Engineering, Wroclaw University of Science and Technology, wyb. St. Wyspianski 27, PL-50-370, Wroclaw, Poland

Faculty of Mechanical Engineering, Wroclaw University of Science and Technology, wyb. St. Wyspianski 27, PL-50-370, Wroclaw, Poland

Combustion Engines 2025,201(2), 14-21

KEYWORDS

TOPICS

ABSTRACT

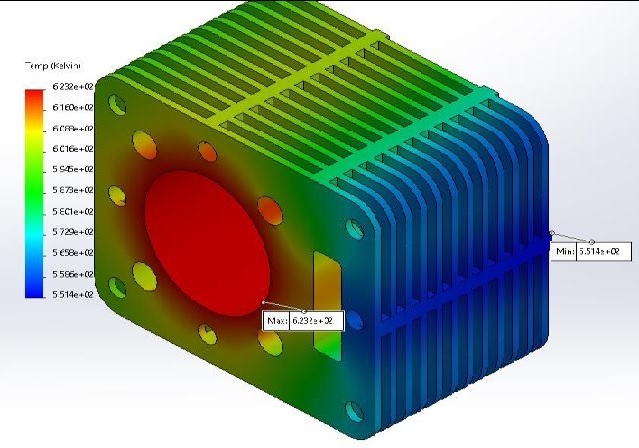

Heat transfer modelling and simulation were carried out in a single-cylinder, four-stroke, air-cooled engine to evaluate the heat transfer rate of the engine block. The modelling studies of cylinders with different numbers of fins and different geometry were performed using the SolidWorks computer platform. The tested components were made of 6063-T6 aluminium alloy castings. The simulation concerned different numbers of fins as well as changing the geometry of fins with circular and rectangular perforations. The results of the studies showed the possibility of improving the power to mass ratio for cylinder efficiency and heat transfer rate. It was shown that a large number of fins leads to an increased heat transfer rate, but it affects the overall engine efficiency due to the increase in the total engine mass. Circular perforation is a better design solution than rectangular perforated fins with the same cross-section. Circular perforation provides a lower engine cylinder mass and gives more than 4 % better heat transfer rate. The perforation size was tested using circular perforations with a diameter of 7.14 mm, 8.5 mm and 10 mm. With a 7.14 mm diameter perforation the heat transfer rate increases slightly compared to the other tested ones, while a 10 mm diameter perforation provides the best mass reduction.

REFERENCES (32)

1.

Abbood MM, Azziz HN, Farhoud EK. Investigating the effects of fin geometry on motorcycle cylinder cooling. IOP Conf Ser: Mater Sci Eng. 2021;1067(1):012102. https://doi.org.10.1088/1757-8....

2.

Ameur H, Menni Y. Laminar cooling of shear thinning fluids in horizontal and baffled tubes: effect of perforation in baffles. Thermal Science and Engineering Progress. 2019;14:100430. https://doi.org/10.1016/j.tsep....

3.

Angamuthu K, Krishnan G, Gowrishankar M, Abraham JG. Modeling and simulation studies of 100 cc motor cycle engine cylinder with groove and perforated fin design using different materials. Mater Today Proc. 2021;42:1447-1455. https://doi.org/10.1016/j.matp....

4.

Barua, A, Pradhan S, Kumari K, Naik B et.al. Comparative evaluation based on FEA of thermal analysis of IC engine cylinder using different materials. Mater Today Proc. 2023. https://doi.org/10.1016/j.matp....

5.

Boukhadia K, Ameur H, Sahel D, Bozit M. Effect of the perforation design on the fluid flow and heat transfer characteristics of a plate fin heat exchanger. Int J Therm Sci. 2017;126:172-180. https://doi.org/10.1016/j.ijth....

6.

Chakradhara Goud S, Chandra Sekhar G. Study on cooling effects in fin type engine cylinders in two wheelers. Think India Journal. 2019;22(11):8908-8915.

7.

Deshmukh PA, Warkhedkar RM. Thermal performance of elliptical pin fin heat sink under combined natural and forced convection. Exp Therm Fluid Sci. 2013;50:61-68. https://doi.org/10.1016/j.expt....

8.

Gokhale A, Karthikeyan N. Optimization of engine cooling through conjugate heat transfer simulation and analysis of fins. SAE Technical Paper 2012-32-0054. 2012. https://doi.org/10.4271/2012-3....

9.

Gore V, Kore S, Nalawade D. Thermal analysis of air-cooled fins. Journal of Emerging Technologies and Innovative Research. 2021;8(12):470-476. https://www.jetir.org/papers/J....

10.

Hassan MASM, Razlan ZM, Bakar SA, Rahman AA et. al. Derivation and validation of heat transfer model for spark-ignition engine cylinder head. Appl Therm Eng. 2023;225:120240. https://doi.org/10.1016/j.appl....

11.

Hatami M, Ganji DD. Thermal performance of circular convective-radiative porous fins with different section shapes and materials. Energ Convers Manage. 2013;76:185-193. https://doi.org/10.1016/j.enco....

12.

Hotta TK, Saija RN, Sigireddy RT, Mugala VS, Nadu T. Design of fins to maximize the heat transfer rate from the engine. International Journal of Mechanical Engineering and Technology. 2018;9(4):213-223.

13.

Hu X, Sun Q, Li G, Bai S. Numerical investigation of thermo-hydraulic performance of an opposed piston opposed cylinder engine water jacket with helical fins. Appl Therm Eng. 2019;159:113824. https://doi.org/10.1016/j.appl....

14.

Ibrahim TK, Mohammed MN, Mohammed MK, Najafi G, Sidik NAC, Basrawi F et al. Experimental study on the effect of perforations shapes on vertical heated fins performance under forced convection heat transfer. Int J Heat Mass Tran. 2018;118:832-846. https://doi.org.10.1016/j.ijhe....

15.

Industry Reports – Africa Two-Wheeler Market Size & Share Analysis – Growth Trends & Forecasts up to 2030 Source. 2023. https://www.mordorintelligence....

16.

Kazem HA, Al-Waeli AliHA, Chaichan MT, Sopian K, Ahmed AA, Wan Nor Roslam WI. Enhancement of photovoltaic module performance using passive cooling (fins): a comprehensive review. Case Studies in Thermal Engineering. 2023;49:103316. https://doi.org/10.1016/j.csit....

17.

Moor J, McKerracher C, O’Donovan A, Cantor C, Fisher R, Soulopoulos N et al. Zero-Emission Vehicles Factbook, A BloombergNEF special report prepared for COP28. 2023. https://assets.bbhub.io/profes....

19.

Mustafaoğlu M, Aksuoğlu OK, Kotcioğlu İ, Güneş Ü, Yeşilyurt MK, Elaty AA. Experimental and numerical investigation of flow and heat transfer in lancet-type-finned cross-flow heat exchangers. Int Commun Heat Mass. 2024;159:108017. https://doi.org/10.1016/j.iche....

20.

Nakashima K, Matsunaga K, Uchiyama Y, Yoshida M. Development of measurement apparatus of piston assembly friction in a small motorcycle engine. Combustion Engines. 2023;194(3):32-37. https://doi.org/10.19206/CE-16....

21.

Nirala RK. Heat transfer rate enhancement of an air cooled four stroke SI engine by geometrically modified fins – a review. Smart Moves Journal IJOSCIENCE. 2018;4(5):31-33. https://doi.org.10.24113/ijosc....

22.

Padmanabhan S, Thiagarajan S., Raj AD, Prabhakaran D, Raju M. Investigation of temperature distribution of fin profiles using analytical and CFD analysis. Mater Today Proc. 2021;44(5):3550-3556. https://doi.org.10.1016/j.matp....

23.

Sachar S, Parvez Y, Khurana T, Chaubey H. Heat transfer enhancement of the air-cooled engine fins through geometrical and material analysis – a review. Mater Today Proc. 2023. https://doi.org.10.1016/j.matp....

24.

Sagar MV, Noll S. Thermal analysis of engine cylinder with fins by using ANSYS workbench. International Journal of Engineering Research & Technology. 2017;6(6):502-514. http://www.ijert.org.

25.

Senthilkumar P, Rejesh Babu S, Koodalingam B, Dharmaprabhakaran T. Design and thermal analysis on circular fin. Mater Today Proc. 202033(7):2901-2906. https://doi.org.10.1016/j.matp....

26.

Shareef SKM, Soivakis M, Arun Kumar N. Design and thermal analysis of engine cylinder fin body using various fin profiles. Mater Today Proc. 2021;47(17):5776-5780. https://doi.org.10.1016/j.matp....

27.

Szymlet N, Rymaniak Ł, Lijewski P, Sokolnicka B, Siedlecki M. Research and analysis of harmful road emissions from a two-wheel vehicle engine in laboratory conditions, Combustion Engines. 2018;173(2):41-46. https://doi.org/10.19206/CE-20....

28.

Teodosio L, Tornatore C, Marchitto L. Numerical evaluation of heat transfer effects on the improvement of efficiency of a spark ignition engine characterized by cylinder variability. Case Studies in Thermal Engineering. 2022;35:102125. https://doi.org.10.1016/j.csit....

29.

Vinoth I. Modelling and analysis of the thermal behavior of air cooling system with fin pitch in I.C. engines. International Journal of Ambient Energy. 2018;41(11):1252-1260. https://doi.org.10.1080/014307....

30.

Wagh VA, Saha SK. Optimising extended fin design and heat transfer coefficient for improved heat transfer and PCM recover time in thermal management of batteries. Appl Therm Eng. 2024;255:123964. https://doi.org/10.1016/j.appl....

31.

Zhang Z, Shen W, Yao W, Wang Q, Zhao W. Effect of helical fins on the combustion performance in a micro-step combustor. Fuel. 2022;319:123718. https://doi.org/10.1016/j.fuel....

32.

Zhou Y, He K, Alizadeh A, AL-Khafaji MO, Alawadi AHR, Maleki H et al. Computational fluid dynamics and multi-objective response surface methodology optimization of perforated-finned heat sinks. J Taiwan Inst Chem E. 2023;145:104823. https://doi.org/10.1016/j.jtic....

CITATIONS (4):

1.

Optimization of the cooling system in a prototype VCR engine using CFD analysis

Mirosław Jakubowski

Combustion Engines

Mirosław Jakubowski

Combustion Engines

2.

Improving heat transfer of air-cooled cylinders with fins with slits

Kohei Nakashima, Masao Yoshida, Kento Nishii, Ayanari Yoshida, Nobuyuki Okura

Combustion Engines

Kohei Nakashima, Masao Yoshida, Kento Nishii, Ayanari Yoshida, Nobuyuki Okura

Combustion Engines

3.

Advancements in hybrid nanofluids for diesel engine thermal management: a comparative review

Gadisa Alemayehu Sufe

Combustion Engines

Gadisa Alemayehu Sufe

Combustion Engines

4.

Thermal Performance Analysis of Engine Cylinder Fins: Design and Simulation Study

Vishal Naranje, Abijith George, Venkata Reddy Poluru, Swapnil Vyavahare, Avinash Badadhe, V. Naranje, R. Vandanapu, A. Khang, S. Salunkhe, D. Armaghani, R. Bhatawdekar, J.P. Davim

EPJ Web of Conferences

Vishal Naranje, Abijith George, Venkata Reddy Poluru, Swapnil Vyavahare, Avinash Badadhe, V. Naranje, R. Vandanapu, A. Khang, S. Salunkhe, D. Armaghani, R. Bhatawdekar, J.P. Davim

EPJ Web of Conferences

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.