Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Method for testing modern common rail piezoelectric fuel injectors

1

Katedra Eksploatacji Pojazdów, Zachodniopomorski Uniwersytet Technologiczny w Szczecinie, Poland

Submission date: 2021-06-15

Final revision date: 2021-07-15

Acceptance date: 2021-07-16

Online publication date: 2021-07-17

Publication date: 2021-09-13

Corresponding author

Tomasz STOECK

Katedra Eksploatacji Pojazdów, Zachodniopomorski Uniwersytet Technologiczny w Szczecinie, Al. Piastów 19, 70-310, Szczecin, Poland

Katedra Eksploatacji Pojazdów, Zachodniopomorski Uniwersytet Technologiczny w Szczecinie, Al. Piastów 19, 70-310, Szczecin, Poland

Combustion Engines 2021,186(3), 31-36

KEYWORDS

TOPICS

ABSTRACT

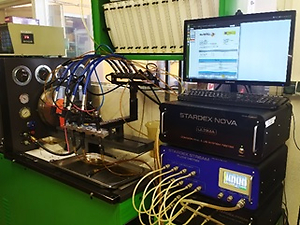

The paper presents the author's own method for testing piezoelectric common rail fuel injectors, which for many years were considered non-repairable components. This was mainly due to the lack of availability of spare parts and dedicated measuring equipment, enabling full diagnostics under test bench conditions. As a result, their workshop and laboratory servicing was very limited, as effective disassembly concerned basicaly only the plunger and barrel assembly (needle with nozzle) for selected reference models. The situation has now improved to such an extent that an author’s own regeneration procedure has been proposed with the replacement of the most important controls and actuators. The tests were carried out on the example of Siemens VDO Continental PCR 2.3 fuel injectors from one engine, listing the most important stages of this process, including the correction of fuel dosage and returns.

ACKNOWLEDGEMENTS

The paper was created thanks to the cooperation with AUTO NEXT SERWIS service company based in Szczecin (Prawobrzeże Quarter), which provided test benches, apparatus and accessories used in the regeneration process of the tested fuel injectors.

REFERENCES (22)

1.

CORBETT, P.J., McINTOSH, A.J.S., GEE, M. et al. Use of ionic liquids to minimize sodium induced internal diesel injector deposits (IDIDs). Molecular Systems Design & Engineering. 2018, 3, 397-407. https://doi.org/10.1039/C7ME00....

2.

CHOMIK, Z., ŁAGOWSKI, P. The analysis of mechanical damage of Common Rail injectors. Journal of Research and Applications in Agricultural Engineering. 2019, 64(1), 13-20.

3.

CZAJKA, J., PIELECHA, I., WISŁOCKI, K. A comparative analysis of diesel fuel injection parameters in piezoelectric and electromagnetic fuel injectors. Combustion Engines. 2009, 138(3), 54-63. https://doi.org/10.19206/CE-11....

4.

EGGER, K., WARGA, J., KLÜGL, W. New common rail injection system with piezo actuation for diesel passenger cars. MTZ worldwide. 2002, 63(9), 14-17.

5.

GÜNTHER, H. Common-Rail-Systeme in der Werk-stattpraxis. Technik, Prüfung, Diagnose, 4th ed., Krafthand Verlag Walter Schultz GmbH. 2012, Bad Wörihofen.

6.

IDZIOR, M., BOROWCZYK T., KARPIUK, W. et al. Możliwości badania stanu technicznego nowoczesnych wtryskiwaczy silników o zapłonie samoczynnym. Logistyka. 2011, 3, 933-942.

7.

IGNACIUK, P., GIL, L. Damages to injectors in diesel engines. Advances in Science and Technology Research Journal. 2014, 21(8), 58-61. https://doi.org/10.12913/22998....

8.

JAKÓBIEC, J., WADRZYK, M., CIEŚLIKOWSKI, B. et al. The process of deposit formation on piezoelectric injector of common rail fuel injection system. Journal of Research and Applications in Agricultural Engineering. 2017, 62(1), 48-54.

9.

KACZOROWSKI, M., PILEWSKI, Z. Wtryskiwacze piezoelektryczne – pionierzy wysokich ciśnień do 2500 barów. Bosch Autospec. 2017, 65(3), 7-10.

10.

KONIECZNY, Ł., ADAMCZYK, B., ADAMCZYK, G. Diagnostyka i regeneracja wtryskiwaczy CR. Zeszyty Naukowe Politechniki Śląskiej. Seria: Transport, 2015, 86, 65-73.

11.

KÖTEN, H., GUNES, E.C., GUNER, K. Piezo-actuated common rail injector structure and efficient design. Journal of Energy Systems. 2018, 2(1), 97-114. https://doi.org/10.30521/jes.4....

12.

KRIVTSOV, S.N., KRIVTSOVA, T.I. Variations in health of piezoelectric elements of the Common Rail electric hydraulic nozzles in the operating conditions. IOP Conference Series: Materials Science and Engineering. 2021, 1061, 1-8. https://doi.org/10.1088/1757-8....

13.

LEE, Y., LEE, C.H. Development of diesel piezo injector driver using microcontrollers. ARPN Journal of Engineering and Applied Sciences. 2018, 13(18), 4860-4865.

14.

MEGA TESTER V3. Software instruction manual version 3.0. The private company "Open System". 2019, Khmelnitsky.

15.

SATKOSKI, C.A., SHAVER, G.M., MORE, R. et al. Dynamic modeling of a piezoelectric actuated fuel injector. Proceedings of the 2009 IFAC Workshop on Engine and Powertrain Control, Simulation and Modeling IFP. 2009, 235-240. http://doi.org/10.3182/2009113....

16.

SHASHANK, M. Piezoelectric diesel injectors & emission control. International Journal of Science and Research. 2015, 4(1), 1-3.

17.

STĘPIEŃ, Z. A study of factors influencing the formation of harmful deposits in the diesel engine injectors. Eksploatacja i Niezawodność – Maintenance and Reliability. 2017, 19(3), 331-337. http://dx.doi.org/10.17531/ein....

18.

STOECK, T. Application of the experimental design technique in fuel dose adjustment of common rail injector. Combustion Engines. 2019, 179(4), 210-215. https://doi.org/10.19206/CE-20....

19.

STOECK, T. Methodology of testing common rail fuel injectors with the use of Gauss`s formulas. Combustion Engines. 2021, 184(1), 11-15. https://doi.org/10.19206/CE-13....

20.

URBAN, J. Study of the car fifth TDI-PCR-2L diesel engine with selective catalytic reduction medial load. Journal of KONES Internal Combustion Engines. 2005, 12, 3-4.

21.

VDO. CR injector test and Repair. Manual Version 1.21. Continental Trading GmbH, 2014, Schwalbach.

22.

ZAJĄC, G., KACZOR, G. Analiza niezawodności wtryskiwaczy. Technical Transactions. Mechanics, Czasopismo Techniczne. Mechanika. 2012, 14(7-M), 327-334.

CITATIONS (3):

1.

Problems of regeneration of modern piezoelectric fuel injectors

Tomasz Stoeck

Combustion Engines

Tomasz Stoeck

Combustion Engines

2.

Influence of dwell time on the hydraulic behaviour utilizing multiple injection strategies and a piezoelectric diesel injector

Ricardo Martínez-Carrillo, la de, Miguel García-Yera, Héctor García-Lara, S Martínez-Martínez

Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering

Ricardo Martínez-Carrillo, la de, Miguel García-Yera, Héctor García-Lara, S Martínez-Martínez

Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering

3.

Diagnostic method for a piezoelectric injector using the Newton-Cotes formula

Tomasz Stoeck

Combustion Engines

Tomasz Stoeck

Combustion Engines

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.