Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Modeling of thermodynamic processes in internal combustion engine cylinder during cranking in compression measurement tests

1

Engine rebuilding equipment, International Motor Bureau, Ukraine

2

Automobile, Kharkiv National Automobile and Highway University, Ukraine

Submission date: 2024-01-22

Final revision date: 2024-03-19

Acceptance date: 2024-04-17

Online publication date: 2024-07-01

Publication date: 2024-08-09

Corresponding author

Alexander Eduard Khrulev

Engine rebuilding equipment, International Motor Bureau, Shkilna str., 15, 07853, Nemishaeve, Kyiv region, Ukraine

Engine rebuilding equipment, International Motor Bureau, Shkilna str., 15, 07853, Nemishaeve, Kyiv region, Ukraine

Combustion Engines 2024,198(3), 98-109

KEYWORDS

TOPICS

ABSTRACT

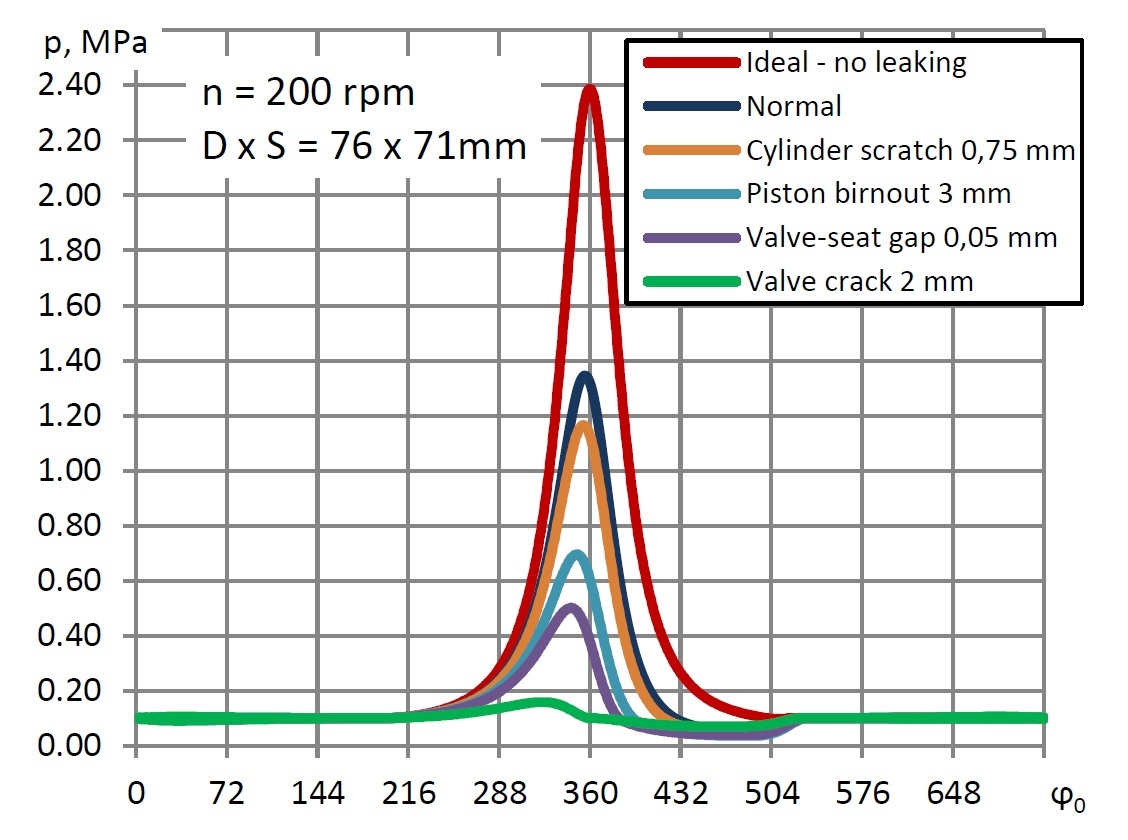

The thermodynamics of in-cylinder processes of the internal combustion engine in cranking mode when measuring compression were examined. Analysis of various theoretical models and comparison of known data showed that the problems of constructing mathematical models of the engine operating cycle remain unresolved. The vast majority of practical data and recommendations for measuring cylinder compression are based on empirical knowledge, numerous experiments and tests. In accordance with this, there is a need for computational models of the compression measurement process and their theoretical justification. To solve the identified problems, a mathematical model of the thermodynamic processes in the cylinder was developed. Unlike existing ones, the model describes the processes in the cylinder step by step, taking into account the real nature of the intake-exhaust processes, air leakage through the interfaces of parts and heat exchange with the walls. Using modeling, the main patterns of changes in compression depending on the modes, the nature of damage to the associated parts of the valve mechanism and cylinder-piston group, the amount of leakage and engine temperature were found. Based on the results of the study, the properties of the model which make its use effective in diagnosing and monitoring the technical condition of engines in operation were concluded.

REFERENCES (36)

1.

Bellér G, Árpád I, Kiss JT, Kocsis D. AVL Boost: a powerful tool for research and education. J Phys Conf Ser. 2021; 1935(1):012015. https://doi.org/10.1088/1742-6....

2.

Blair GP. Design and simulation of four-stroke engines. Warrendale: Society of Automotive Engineers, 1999.

3.

Borowski G, Ghazal O. Use of water injection technique to improve the combustion efficiency of the spark-ignition engine: a model study. Journal of Ecological Engineering. 2019;20(2):226-233. https://doi.org/10.12911/22998....

4.

Burrows JA. An investigation into the cold start performance of automotive diesel engines. Doctoral Thesis. University of Nottingham 1998.

5.

Cordon D, Dean C, Steciak J, Beyerlein S. One-dimensional engine modeling and validation using Ricardo WAVE. Final Report KLK434-B, N07-09. National Institute for Advanced Transportation Technology. University of Idaho; 2007. https://www.academia.edu/18805....

6.

Denton T. Advanced automotive fault diagnosis. 2nd edition. Oxford: Elsevier Butterworth-Heinemann 2006.

7.

Ferguson CR, Kirkpatrick AT. Internal combustion engines: applied thermosciences. 3rd ed. Chichester: John Wiley & Sons 2016.

8.

Fygueroa S, Villamar C, Fygueroa O. Thermodynamic study of the working cycle of a direct injection compression ignition engine. Internal combustion engines. IntechOpen. 2016:75-112. https://doi.org/10.5772/50028.

9.

Gilles T. Automotive engines: diagnosis, repair and rebuilding. 6th ed. Cengage Learning, Delmar 2011.

10.

Gupta HN. Fundamentals of internal combustion engines. PHI Learning Pvt. Ltd. Delhi 2012.

11.

Halderman JD. Automotive technology. principles, diagnosis, and service. 4th ed. New Jersey: Pearson Education 2012.

12.

Heywood JB. Internal combustion engine fundamentals. 2nd ed. McGraw-Hill Education, New York 2018.

13.

Kalikatzarakis M, Coraddu A, Theotokatos G, Oneto L. Development of a zero-dimensional model and application on a medium-speed marine four-stoke diesel engine. Proceedings of MOSES2021 Conference. 3rd International Conference on Modelling and Optimisation of Ship Energy Systems. 2021. https://www.researchgate.net/p....

14.

Kastner LJ, Williams TJ, White JB. Poppet inlet valve characteristics and their influence on the induction process. Proc Inst Mech Eng S. 1963;178(l):955-975. https://doi.org/10.1177/002034....

15.

Khrulev A. Analysis of pneumatic catapult launch system parameters, taking into account engine and UAV characteristics. Advanced UAV. 2023;3(1):10-24. https://publish.mersin.edu.tr/....

16.

Khrulev A, Dmitriev S. Study of the conrod deformation during piston interaction with liquid in the internal combustion engine cylinder. J Mech Eng Sci. 2019;14(2):6557-6569. https://doi.org/10.15282/jmes..... 03.0515.

17.

Lanlege DI, Kehinde R, Sobanke DA, Garba UM. Comparison of Euler and Range-Kutta methods in solving ordinary differential equations of order two and four. Leonardo Journal of Sciences. 2018;32:10-37. https://www.researchgate.net/p..._ Comparison_of_Euler_and_Range-Kutta_methods_in_ solving_ordinary_differential_equations_of_order_two_ and_four.

18.

Magdas VB, Mastan DC, Burnete N. Simulation possibilities of the internal combustion engine management elements using Lotus Engine Simulation software. IOP Conf Ser: Mater Sci Eng. 2020;997(1),012121. https://doi.org/10.1088/1757-8....

19.

Martyr AJ, Plint MA. Engine testing. Theory and practice. 3rd ed. Elsevier Ltd. Oxford 2007.

20.

Martyr AJ, Rogers DR. Engine testing. Electrical, hybrid, IC engine and power storage testing and test facilities. 5th ed. Oxford: Elsevier Ltd. 2021.

21.

Maurya RK. Reciprocating engine combustion diagnostics. In-cylinder pressure measurement and analysis. Cham: Springer 2019. https://doi.org/10.1007/978-3-....

22.

Medina A, Curto-Risso PL, Hernández AC, Guzmán-Vargas L, Angulo-Brown F, Sen AK. Quasi-dimensional simulation of spark ignition engines. From thermodynamic optimization to cyclic variability. Springer-Verlag, London 2014.

23.

Neumann S. Integrated cylinder pressure measurement for gas engine control. Combustion Engines. 2011;146(3):16-23. https://doi.org/10.19206/CE-11....

24.

Orczyk M, Tomaszewski F. Diagnostic and reliability model of an internal combustion engine. Combustion Engines. 2020;180(1):41-46. https://doi.org/10.19206/CE-20....

25.

Pacaud P, Perrin H, Laget O. Cold start on diesel engine: is low compression ratio compatible with cold start requirements? SAE Int J Engines. 2009;1(1):831-849. https://doi.org/10.4271/2008-0....

26.

Pressure School. Part 2: A running diagnosis by Pico Technology. Garage Lube. https://www.garagelube.com/ online-training/pressure-school-part-2-running-diagnosis/.

27.

Pressure School. Part 1: Introduction to the pressure transducer by Pico Technology. Garage Lube. https://www.garagelube.com/onl....

28.

Pszczółkowski J. The model for cylinder charge parameters during engine starting. Combustion Engines. 2022;188(1):60-66. https://doi.org/10.19206/CE-14....

29.

Reißig M. Modeling the cold start process of spark ignition engines. Dissertation zur Erlangung des akademischen Grades Doktor-Ingenieur der Fakultat fur Maschinenbau und Schiffstechnik der Universitat Rostock. Lehrstuhl fur Technische Thermodynamik. Universitat Rostock 2012.

30.

Roberts A, Brooks R, Shipway P. Internal combustion engine cold-start efficiency: a review of the problem, causes and potential solutions. Energ Convers Manage. 2014;82:327-350. https://doi.org/10.1016/j.enco.... 03.002.

31.

Saraieva IY. Improving the process of diagnosing cylinder-piston group and tightness of valves in a gasoline car engine: Dissertation. National Aerospace University n.a. N.E. Zhukovsky "Kharkov Aviation Institute" 2006.

32.

Saraіeva I, Beketov D. Analysis of diagnostic method of engine piston-cylinder-unit using «Bosch» equipment. Automobile transport. 2010;27:56-60. https://api.dspace.khadi.khark....

33.

Saraieva I, Khrulev A, Vorobiov O. Development of mathematical criteria for assessing the quality of diagnosing the cylinder-piston group of a car engine. Vehicle and Electronics. Innovative Technologies. 2022;22:92-103. https://doi.org/10.30977/VEIT.....

34.

Saraieva I, Khrulev A, Vorobiov O, Sebko D. Digital diagnostics for determining the tightness of the combustion camera of the car engine. Vehicle and Electronics. Innovative Technologies. 2020;18:52-64. https://doi.org/10.30977/VEIT.....

35.

Stotsky AA. Automotive engines. Control, estimation, statistical detection. Heidelberg: Springer-Verlag Berlin 2009. https://doi.org/10.1007/978-3-....

36.

Witkowski K. The issue of the indicator diagram analysis for the purpose of diagnosis of marine diesel engines. Journal of KONES Powertrain and Transport. 2015;22(2):293-298. https://doi.org/10.5604/123140....

CITATIONS (1):

1.

Diagnosis of marine internal combustion engines by means of rapidly variable temperature and composition of exhaust gas as an alternative or support for currently used diagnostic methods

Patrycja Puzdrowska

Combustion Engines

Patrycja Puzdrowska

Combustion Engines

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.