Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Numerical evaluation of urea-mixing devices for close-coupled selective catalytic reduction systems

1

Faculty of Power and Aeronautical Engineering, Warsaw University of Technology, Poland

Submission date: 2023-01-14

Final revision date: 2023-03-13

Acceptance date: 2023-03-26

Online publication date: 2023-04-07

Publication date: 2023-06-14

Corresponding author

Bartosz Grzegorz Kaźmierski

Faculty of Power and Aeronautical Engineering, Warsaw University of Technology, Nowowiejska 21/25, 00-665, Warszawa, Poland

Faculty of Power and Aeronautical Engineering, Warsaw University of Technology, Nowowiejska 21/25, 00-665, Warszawa, Poland

Combustion Engines 2023,193(2), 84-93

KEYWORDS

TOPICS

ABSTRACT

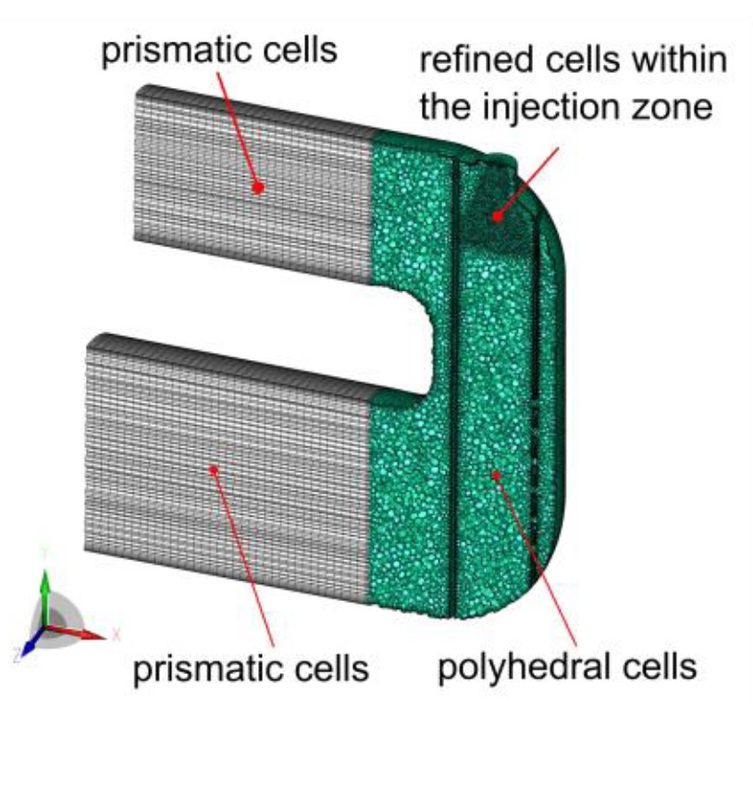

The following research presents a numerical evaluation of existing and conceptual urea-mixing devices used in close-coupled (to the engine) selective catalytic reduction (SCR) systems. The analysis was aimed at the assessment of urea-mixing devices that could considerably enhance the reduction of nitrogen oxides from the diesel-engine combustion process under a wide range of operating conditions, including cold starts.

The analysis showed that replacing blade-equipped static mixers with perforated stationary mixing devices may provide a more uniform spatial distribution of ammonia at the inlet to the SCR catalyst and reduce pressure drops generated by mixing devices. Moreover, the conceptual mixing devices, based on combinations of the blade and perforated mixers to develop intensive turbulence, enabled the increase of the mixing length leading to effective decomposition of the urea-water solution (UWS), and provided uniform spatial distribution of ammonia, even for the small-sized mixing systems. However, the intensive mixing was often associated with a significant rise in the pressure drop.

REFERENCES (54)

1.

Bai C, Liu K, Zhao T et al. Study on spray characteristics and breakup mechanism of an SCR injector. Appl Sci. 2022;12(18). https://doi.org/10.3390/app121....

2.

Birkhold F. Selektive katalytische Reduktion von Stickoxiden in Kraftfahrzeugen: Untersuchung der Einspritzung von Harnstoffwasserlösung. Shaker Verlag GmbH, 2007.

3.

Birkhold F, Meingast U, Wassermann P et al. Modeling and simulation of the injection of urea-water-solution for automotive SCR DeNOx-systems. Appl Catal B: Environmental. 2007;70(1-4):119-127. https://doi.org/10.1016/j.apca....

4.

Börnhorst M, Deutschmann O. Advances and challenges of ammonia delivery by urea-water sprays in SCR systems. Prog Energ Combust. 2021;(87):100949. https://doi.org/10.1016/j.pecs....

5.

Boruc Ł, Rogoz R, Bachanek J et al. An experimental facility for rapid testing of SCR systems. SAE Technical Paper 2020-01-2192. 2020. https://doi.org/10.4271/2020-0....

6.

Bracho G, Postrioti L, Moreno A et al. Experimental study of the droplet characteristics of a SCR injector spray through optical techniques. Int J Multiphas Flow. 2021;(135):103531. https://doi.org/10.1016/j.ijmu....

7.

Capetillo AJ, Ibarra F, Stepniewski D et al. Multiphase modelling of SCR systems: using the Taguchi method for mixer optimisation. SAE Int J Engines. 2017;10(1):61-71. https://doi.org/10.4271/2017-2....

8.

Dukowicz JK. A particle-fluid numerical model for liquid sprays. J Comput Phys. 1980;35(2):229-253.

9.

Fernández E, Ortego A, Valero A et al. Suitability assessment of NOx emissions measurements with PTI equipment. Vehicles. 2022;4(4):917-941. https://doi.org/10.3390/vehicl....

10.

Forchheimer P. Wasserbewegung durch boden. Zeitschrift des Vereins deutscher Ingenieure, 45th edition. 1901.

11.

Fu H, Huang Z, Tang C et al. Effect of mixer structure on liquid film formation and NOx conversion efficiency in selective catalytic reduction system. Fuel. 2022;(330):125405. https://doi.org/10.1016/j.fuel....

12.

Gosman AD, Loannides E. Aspects of computer simulation of liquid-fueled combustors. J Energy. 1983;7(6):482-490. https://doi.org/10.2514/3.6268....

13.

Górka K, Kaźmierski B, Kapusta ŁJ. Numerical analysis of the flow rig for UWS spray examination in exhaust system-relevant conditions. Combustion Engines. 2021;186(3):103-112. https://doi.org/10.19206/CE-14....

14.

Grout S, Blaisot J-B, Pajot K et al. Experimental investigation on the injection of an urea–water solution in hot air stream for the SCR application: evaporation and spray/wall interaction. Fuel. 2013;106(x):166-177. https://doi.org/10.1016/j.fuel....

15.

Hanjalić K, Popovac M, Hadžiabdić M. A robust near-wall elliptic-relaxation eddy-viscosity turbulence model for CFD. Int J Heat Fluid Fl. 2004;25(6):1047-1051. https://doi.org/10.1016/j.ijhe....

16.

Huang H, Chen Y, Li Z et al. Analysis of deposit formation mechanism and structure optimization in urea-SCR system of diesel engine. Fuel. 2020;(265):116941. https://doi.org/10.1016/j.fuel....

17.

Huang H, Zhang L, Chen Y et al. Study on decomposition and by-products formation mechanism of urea solution impinging on heated plate in SCR system. Chemosphere. 2022;(309): 136620. https://doi.org/10.1016/j.chem....

18.

Hui Z, Boyan X, Chuansheng W. Numerical simulation to reduce NOx of diesel engine urea-SCR system. Open Mechanical Engineering Journal. 2014;8(2):643-647. https://doi.org/10.2174/187415....

19.

Jang J, Na S, Roh H et al. Spraying and mixing characteristics of urea in a static mixer applied marine SCR system. Energies. 2021;14(18). https://doi.org/10.3390/en1418....

20.

Kandylas IP, Stamatelos AM. Engine exhaust system design based on heat transfer computation. Energ Convers Manage. 1999;40(10):1057-1072. https://doi.org/10.1016/S0196-....

21.

Kapusta ŁJ, Rogoz R, Bachanek J. Experimental and numerical study to evaluate the effect of flash boiling on urea-water solution sprays and SCR system performance. Atomization Spray. 2021;31(5):89-117. https://doi.org/10.1615/Atomiz....

22.

Kapusta ŁJ, Rogoz R, Bachanek J et al. Low-pressure injection of water and urea-water solution in flash-boiling conditions. SAE Int J Adv Curr Pract Mobility. 2020;3(1):365-377. https://doi.org/10.4271/2020-0....

23.

Kaźmierski B, Górka K, Kapusta ŁJ. A conceptual design and numerical analysis of the mixerless urea-SCR system. Combustion Engines. 2021;187(4):12-20. https://doi.org/10.19206/CE-14....

24.

Kaźmierski B, Kapusta ŁJ. The importance of individual spray properties in performance improvement of a urea-SCR system employing flash-boiling injection. Appl Energ. 2023;(329):120217. https://doi.org/10.1016/j.apen....

25.

Kim HJ, Lee SH, Kwon SI et al. Investigation of the emission characteristics of light-duty diesel vehicles in Korea based on Euro-VI standards according to type of after-treatment system. Energies. 2020;13(18). https://doi.org/10.3390/en1318....

26.

Kim JY, Ryu SH, Ha JS. Numerical prediction on the characteristics of spray-induced mixing and thermal decomposition of urea solution in SCR system. Proceedings of the ASME 2004 Internal Combustion Engine Division Fall Technical Conference. 2004:165-170. https://doi.org/10.1115/ICEF20....

27.

Kuhnke D. Spray/Wall-Interaction Modelling by Dimensionless Data Analysis. Shaker Verlag GmbH, 2004.

28.

Kulkarni AP, Megaritis T, Ganippa LC. Impact dynamics and morphology of urea-water-solution droplets impinging on a hot plate under urea-SCR relevant conditions: influence of surface tension. Fuel. 2021;(298):120671. https://doi.org/10.1016/j.fuel....

29.

Lee C. Numerical and experimental investigation of evaporation and mixture uniformity of urea–water solution in selective catalytic reduction system. Transport Res D-Tr E. 2018;(60):210-224. https://doi.org/10.1016/j.trd.....

30.

Li M, Zhang Y, Liu X et al. Numerical investigation on the urea deposit formation process in a selective catalytic reduction system of a diesel engine based on a fluid–solid coupling method. ACS Omega. 2021;6(8):5921-5932. https://doi.org/10.1021/acsome....

31.

Maizak D, Wilberforce T, Olabi AG. DeNOx removal techniques for automotive applications – a review. Environ Adv. 2020;(2):100021. https://doi.org/10.1016/j.enva....

32.

Majewski WA, Ambs JL, Bickel K. Nitrogen oxides reactions in diesel oxidation catalyst. SAE Technical Paper 950374. 1995. https://doi.org/10.4271/950374.

33.

Mehdi G, Zhou S, Zhu Y et al. Numerical investigation of SCR mixer design optimization for improved performance. Processes. 2019;7(3). https://doi.org/10.3390/pr7030....

34.

Mera Z, Fonseca N, López J-M et al. Analysis of the high instantaneous NOx emissions from Euro 6 diesel passenger cars under real driving conditions. Appl Energ. 2019;(242):1074-1089. https://doi.org/10.1016/j.apen....

35.

Michelin J, Guilbaud F, Guil A et al. Advanced compact SCR mixer: BlueBox. SAE Technical Paper 2014-01-1531. 2014. https://doi.org/10.4271/2014-0....

36.

Michelin J, Nappez P, Guilbaud F et al. Advanced close coupled SCR compact mixer architecture. SAE Technical Paper 2015-01-1020. 2015. https://doi.org/10.4271/2015-0....

37.

Millo F, Sapio F, Paradisi BP et al. Experimental and numerical analysis of an innovative mixer geometry for urea injection in SCR applications. Emiss Control Sci Technol. 2022;8(1-2):78-95. https://doi.org/10.1007/s40825....

38.

Musa SNA, Saito M, Furuhata T et al. Evaporation characteristics of a single aqueous urea solution droplet. ICLASS. 2006.

39.

Pang Z, Chen R, Cao Y. Performance analysis and optimization for static mixer of SCR denitration system under different arrangements. Energies. 2022;15(23). https://doi.org/10.3390/en1523....

40.

Park T, Sung Y, Kim T et al. Effect of static mixer geometry on flow mixing and pressure drop in marine SCR applications. Int J Nav Arch Ocean. 2014;6(1):27-38. https://doi.org/10.2478/IJNAOE....

41.

Payri R, Bracho G, Martí-Aldaraví P et al. Computational study of urea–water solution sprays for the analysis of the injection process in SCR-like conditions. Ind Eng Chem Res. 2020;59(41):18659-18673. https://doi.org/10.1021/acs.ie....

42.

Payri R, Marti-Aldaravi P, Bracho G et al. Numerical analysis of the injection angle of urea-water sprays for the ammonia generation in realistic test conditions. SAE Technical Paper 2022-01-0584. 2022. https://doi.org/10.4271/2022-0....

43.

Popovac M, Hanjalic K. Compound wall treatment for RANS computation of complex turbulent flows and heat transfer. Flow Turbul Combust. 2007;78(2):177. https://doi.org/10.1007/s10494....

44.

Rogóż R, Kapusta ŁJ, Bachanek J et al. Improved urea-water solution spray model for simulations of selective catalytic reduction systems. Renew Sust Energ Rev. 2020;120:109616. https://doi.org/10.1016/j.rser....

45.

Schaber PM, Colson J, Higgins S et al. Thermal decomposition (pyrolysis) of urea in an open reaction vessel. Thermochim Acta. 2004;424(1-2):131-142. https://doi.org/10.1016/j.tca.....

46.

Schiller L, Naumann Z. A drag coefficient correlation. in Z.Ver.Deutsch.Ing, 1935, 77(13-14):318-320.

47.

Tan L, Feng P, Yang S et al. CFD studies on effects of SCR mixers on the performance of urea conversion and mixing of the reducing agent. Chem Eng Process – Process Intensif. 2018;(123):82-88. https://doi.org/10.1016/j.cep.....

48.

Wang TJ, Baek SW, Lee SY et al. Experimental investigation on evaporation of urea-water-solution droplet for SCR applications. AIChE Journal. 2009;55(12):3267-3276. https://doi.org/10.1002/aic.11....

49.

Xu Z, Liu J, Fu J. Experimental investigation on the urea injection and mixing module for improving the performance of urea-SCR in diesel engines. Can J Chem Eng. 2018;96(6):1417-1429. https://doi.org/10.1002/cjce.2....

50.

Ye J, Lv J, Tan D et al. Numerical analysis on enhancing spray performance of SCR mixer device and heat transfer performance based on field synergy principle. Processes. 2021;9(5). https://doi.org/10.3390/pr9050....

51.

Zhang C, Sun C, Wu M et al. Optimisation design of SCR mixer for improving deposit performance at low temperatures. Fuel. 2019;(237):465-474. https://doi.org/10.1016/j.fuel....

52.

Zhao C, Lou D, Zhang Y et al. Application study on a new hybrid canning structure of after-treatment system for diesel engine. Energies. 2020;13(3). https://doi.org/10.3390/en1303....

53.

Zheng G, Palmer G, Salanta G et al. Mixer development for urea SCR applications. SAE Technical Paper 2009-01-2879. 2009. https://doi.org/10.4271/2009-0....

54.

Zhu N, Lv L, Ye C. Component analysis of deposits in selective catalytic reduction system for automotive diesel engine. MATEC Web Conf. 2016;(51):03006. https://doi.org/10.1051/matecc....

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.