Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Problems of selecting filter partition in passenger car engine intake air filters

1

Military University of Technology, Faculty of Mechanical Engineering, Military University of Technology, Poland

2

Faculty of Mechanical Engineering, Institute of Vehicles and Transport, Military University of Technology, Warsaw, Poland, Poland

Submission date: 2021-06-16

Final revision date: 2021-06-29

Acceptance date: 2021-06-30

Online publication date: 2021-07-01

Publication date: 2021-07-01

Corresponding author

Tadeusz Dziubak

Military University of Technology, Faculty of Mechanical Engineering, Military University of Technology, Poland

Military University of Technology, Faculty of Mechanical Engineering, Military University of Technology, Poland

Combustion Engines 2021,185(2), 44-58

KEYWORDS

TOPICS

ABSTRACT

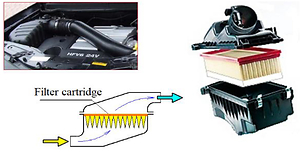

The aim of this study was to verify the criteria for selecting pleated filter partitions used in passenger car engine filters. The paper presents the problem of optimizing pleated air filters in the dir

ection of minimizing pressure drop, which is the source of engine energy losses. Two criteria for selection of a paper filter partition for specific operating conditions of the filter and the engine are presented: criterion of permissible separation speed and criterion of permissible pressure drop. The actual filtration area of 44 paper pleated filter elements used in passenger cars and the air stream flowing through the filter were determined, which made it possible to calculate separation speed. In 62% of the analyzed filter inserts, the calculated separation speeds are within the speed range recommended by the constructors, Fmax = 0,06-0,12 m/s. Exceeding permissible separation speed Fmax = 0,12 m/s was found mainly in supercharged engines. Negative effects of engine operation with an air filter with too small separation area are presented, in the form of increased pressure drop and energy loss of the engine as well as shorter car mileage to reach permissible pressure drop.

FUNDING

This work was financed by Military University of Technology under research project UGB 881/2021

REFERENCES (58)

1.

ALLAM, S., ELSAID, A.M. Parametric study on vehicle fuel economy and optimization criteria of the pleated air filter designs to improve the performance of an I.C diesel engine: experimental and CFD approaches. Separation and Purification Technology. 2020, 241, 116680. https://doi.org/10.1016/j.sepp....

2.

BARBOLINI, M., DI PAULI, F., TRAINA, M. Simulation der Luftfiltration zur Auslegung von Filterelementen. MTZ Motortechnische Zeitschrift. 2014, 75(11), 52-57.

3.

BARRIS, M.A. Total FiltrationTM. The influence of filter selection on engine wear. Emissions and performance. SAE Technical Paper 952557. 1995. https://doi.org/10.4271/952557.

4.

BOJDO, N., FILIPPONE, A. Effect of desert particulate composition on helicopter engine degradation rate. 40th European Rotorcraft Forum. Southampton. 2014. https://doi.org/10.13140/2.1.2....

5.

BRAUN, R., SAUTER, H., SEGGERN, J. et al. Motorluft-filtration. MTZ-Motortechnische Zeitschrift. 2006, 67(12), 974-980. https://doi.org/10.1007/bf0322....

6.

BUGLI, N.J., GREEN, G.S. Performance and benefits of zero maintenance air induction systems. SAE Technical Paper 2005-01-1139. 2005. https://doi.org/10.4271/2005-0....

7.

CHEN, D.R., PUI, D.Y.H., LIU, B.Y.H. Optimization of pleated filter designs using a finite-element numerical model. Aerosol Science and Technology. 1995, 23(4), 579-590. https://doi.org/10.1080/027868....

8.

CHEN, C.W., HUANG, S.H., CHIANG, C.M. et al. Filter quality of pleated filter cartridges. Annals of Occupational Hygiene. 2008, 52(3), 207-212. https://doi.org/10.1093/annhyg....

9.

DAHLAN, A.A., MUHAMMAD, SAID M.F., ABDUL LATIFF, Z. et al. Acoustic study of an air intake system of SI engine using 1-dimensional approach. International Journal of Automotive and Mechanical Engineering (IJAME). 2019, 16(1), 6281-6300. https://doi.org/10.15282/ijame....

10.

DEL FABBRO, L., LABORDE, J.C., MERLIN, P. et al. Air flows and pressure drop modelling for different pleated industrial filters. Filtration & Separation. 2002, 39(1), 35-40. https://doi.org/10.1016/S0015-....

11.

DURST, M., KLEIN, G., MOSER, N. Filtration in Fahrzeugen. Mann+Hummel GMBH. Ludwigsburg 2005.

12.

DZIUBAK, T., DZIUBAK, S.D. Experimental study of filtration materials used in the car air intake. Materials. 2020, 13(16), 3498. https://doi.org/10.3390/ma1316....

13.

DZIUBAK, T., BĄKAŁA, L. Experimental research of the material filtration characteristics with nanofibers addition. Journal of KONES Powertrain and Transport. 2018, 25(4), 83-94. https://doi.org/10.5604/01.300....

14.

DZIUBAK, T., SZWEDKOWICZ, S. Operating properties of non-woven fabric panel filters for internal combustion engine inlet air in single and two-stage filtration systems. Eksploatacja i Niezawodność – Maintenance and Reliability. 2015, 17(4), 519-527. https://doi.org/10.17531/ein.2....

16.

ERDMANNSDÖRFER, H. Lesttingmoglichkeiten von Papierfiltern zur Reinigung der Ansaugluft von Diselmotoren. MTZ-Motortechnische Zeitschrift. 1971, 32, 123-131.

17.

FENG, Z., LONG, Z. Modeling unsteady filtration perfor-mance of pleated filter. Aerosol Science and Technology. 2016, 50(6), 626-637. https://doi.org/10.1080/027868....

18.

FLECK, S., HEIM, M., BECK, A. et al. Realitätsnahe Prüfung von Motoransaugluftfiltern, MTZ-Motortechnische Zeitschrift. 2009, 70, 414-418. https://doi.org/10.1007/BF0322....

19.

FOTOVATI, S., HOSSEINI, S., TAFRESHI, H. et al. Mod-eling instantaneous pressure drop of pleated thin filter me-dia during dust loading, Chemical Engineering Science. 2011, 66(18), 4036-4046. https://doi.org/10.1016/j.ces.....

20.

FOTOVATI, S., TAFRESHI, H.V., POURDEYHIMI, B. A macroscopic model for simulating pressure drop and collection efficiency of pleated filters over time. Separation and Purification Technology. 2012, 98, 344-355. https://doi.org/10.1016/j.sepp....

21.

GERVAIS, P.C., POUSSIER, S., BARDIN-MONNIER, N. et al. Combination of single-photon emission and X-Ray computed tomography to visualize aerosol deposition in pleated filter. Separation and Purification Technology. 2014, 126, 52-61. https://doi.org/10.1016/j.sepp....

22.

HALIM, M.A.A., MOHD, N.A.R., NASIR, M.N.M. et al. Experimental and numerical analysis of a motorcycle air intake system aerodynamics and performance. International Journal of Automotive and Mechanical Engineering (IJAME). 2020, 17(1), 7607-7617. https://doi.org/10.15282/ijame.

23.

JAROSZCZYK, T., FALLON, S.L., LIU, Z.G. et al. Devel-opment of a method to measure engine air cleaner fractional efficiency. SAE Technical Paper 1999-01-0002. 1999. https://doi.org/10.4271/1999-0....

24.

JIN-RUI, X., FU-PING, Q., JIN-LI, L. et al. Three-dimensional microstructure reconstruction of pleated air filter media and simulation of its performance in dust filtration stage. Chinese Journal of Process Engineering. 2017, 17(1) 170-177. https://doi.org/10.12034/j.iss....

25.

KAHRSTEDT, J., ZÜLCH, S., STRENG, CH. et al. Neue Generation Des 3.0-L-Tdi-Motors Von Audi. MTZ-Motortechnische Zeitschrift. 2010, 11(71), 800-807. https://doi.org/10.1007/BF0322....

26.

KANG, S., BOCK, N., SWANSON, J. et al. Characteriza-tion of pleated filter media using particle image velocimetry. Separation and Purification Technology. 2020, 237, 116333. 116333. https://doi.org/10.1016/j.sepp....

27.

LI, S., HU, S., XIE, B. et al. Influence of pleat geometry on the filtration and cleaning characteristics of filter media. Separation and Purification Technology. 2019, 210, 38-47. https://doi.org/10.1016/j.sepp....

28.

LONG, J., TANG, M., SUN, Z. et al. Dust loading perfor-mance of a novel submicro-fiber composite filter medium for engine. Materials. 2018, 11, 2038. https://doi.org/10.3390/ma1110....

29.

MAHESH, J. Parametric study and CFD analysis of air filter. Asian Journal of Convergence in Technology (AJCT). 2019, 5(1), 1-9. www.asianssr.org.

30.

MADDINENI, A.K., DAS, D, DAMODARAN, R.M. Experimental and numerical study on automotive pleated air filters. SAE Technical Paper 2016-28-0100. 2016. https://doi.org/10.4271/2016-2....

31.

MADDINENI, A.K., DAS, D., DAMODARAN, R.M. Air-borne particle by fibrous filter media under collision effect: a CFD-based approach. Separation and Purification Technology. 2018, 193, 1-10. https://doi.org/10.1016/j.sepp....

32.

MADDINENI, A.K., DAS, D., DAMODARAN, R.M. Numerical investigation of pressure and flow characteristics of pleated air filter system for automotive engine intake application. Separation and Purification Technology. 2019, 212, 126-134. https://doi.org/10.1016/j.sepp....

33.

MADDINENI, A.K., DAS, D., DAMODARAN, R.M. Oil-treated pleated fibrous air filters for motor vehicle engine intake application. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 2019, 234(2-3), 702-713. https://doi.org/10.1177/095440....

34.

MELZER, H.H., BROX, W. Ansauggerauschdampfer und Luftfilter für BMW 524 td, MTZ-Motortechnische Zeitschrift. 1984, 45, 223-227.

35.

KWON, M-S., KIM Y-L., KIM, M-S. et al. Effect of pleat-ing ratio on quality factor of pleated filter in air purifier. Journal of Korean Society for Atmospheric Environment. 2020, 36(1), 119-127. https://doi.org/10.5572/KOSAE.....

36.

MUSTAFA, N.S., NGADIMAN, N.H.A., ABAS, M.A. et al. Application of box-behnken analysis on the optimisation of air intake system for a naturally aspirated engine. International Journal of Automotive and Mechanical Engineering (IJAME). 2020, 17(2), 7607-7617. https://doi.org/10.15282/ijame....

37.

NORMAN, K., HUFF, S., WEST, B. Effect of intake air filter condition on vehicle fuel economy. U.S. Department of Energy (DOE) Information Bridge. 2009. http://www.osti.gov/bridge.

38.

PARK, B., LEE, M., JO, Y. et al. Influence of pleat geometry on filter cleaning in a PTFE/glass composite filter. Journal of the Air & Waste Management Association. 2012, 62, 1257-1263. https://doi.org/10.1080/109622....

40.

REBAI, M., PRAT, M., MEIRELES, M. et al. A semi-analytical model for gas flow in pleated filters. Chemical Engineering Science. 2010, 65, 2835-2846. https://doi.org/10.1016/j.ces.....

41.

REBAI, M., PRAT, M., MEIRELES, M. et al. Clogging modeling in pleated filters for gas filtration. Chemical Engineering Research and Design. 2010, 88, 476-486. https://doi.org/10.1016/j.cher....

42.

[42] SAKTHIVEL, S., EHZIL ANBAN, J.J., RAMACHAN-DRAN, T. Development of needle-punched nonwoven fabrics from reclaimed fibers for air filtration applications. Journal of Engineered Fibers and Fabrics. 2014, 9, 149-154. https://doi.org/10.1177/155892...

43.

SALEH, A., TAFRESHI, H. A simple semi-numerical model for designing pleated air filters under dust loading. Separation and Purification Technology. 2014, 137, 94-108. https://doi.org/10.1016/j.sepp....

44.

SALEH, A.M., HOSSEINI, S.A., TAFRESHI, H.V. et al. 3-D microscale simulation of dust-loading in thin flat-sheet filters: a comparison with 1-D macroscale simulations. Chemical Engineering Science. 2013, 99, 284-291. https://doi.org/10.1016/j.ces.....

45.

SALEH, A.M., FOTOVATI, S., TAFRESHI, H.V. et al. Modeling service life of pleated filters exposed to poly-dispersed aerosols. Powder Technology. 2014, 266, 79-89. https://doi.org/10.1016/j.powt....

46.

SALEH, A.M., TAFRESHI, H.V., POURDEYHIMI, B. Service life of circular pleated filters vs. that of their flat counterpart. Separation and Purification Technology. 2015, 156, 881-888. https://doi.org/10.1016/j.sepp....

47.

SAWANT, P., BARI, S. Effects of variable intake valve timings and valve lift on the performance and fuel efficiency of an internal combustion engine. SAE Technical Paper 2018-01-0376. 2018. https://doi.org/10.4271/2018-0....

48.

SMIALEK, J.L., ARCHER, F.A., GARLICK, R.G. Turbine airfoil degradation in the persian gulf war. The Journal of The Minerals, Metals & Materials Society (TMS). 1994, 46(12), 39-41. https://doi.org/10.1007/BF0322....

49.

SUBRENAT, A., BELLETRE, J., LE CLOIREC, P. 3-D numerical simulations of flows in a cylindrical pleated filter packed with activated carbon cloth. Chemical Engineering Science. 2003, 58, 4965-4973. https://doi.org/10.1016/j.ces.....

50.

TANG, R-J., HU, B-F., ZHANG, M. et al. Study on separation characteristics of dust and droplet on air intake pre-filtration systems of CV based on CFD simulation and test. International Conference on Artificial Intelligence and Computing Science (ICAICS 2019). https://doi.org/10.12783/dtcse... icaic2019/29462.

51.

TAUFKIRCH, G., MAYR, G. Papierluftfilter für Motoren in Nutzfahrzeugen. MTZ-Motortechnische Zeitschrift. 1984, 45(3), 95-105.

52.

THÉRON, F., JOUBERT, A., COQ, L. Numerical and experimental investigations of the influence of the pleat geometry on the pressure drop and velocity field of a pleated fibrous filter. Separation and Purification Technology. 2017, 182, 69-77. https://doi.org/10.1016/j.sepp....

53.

TRONVILLE, P., SALA, R. Minimization of resistance in pleated-media air filter designs: empirical and CFD ap-proaches. HVAC&R Research. 2003, 9, 95-106. https://doi.org/10.1080/107896....

54.

WIEGMANN, A., RIEF, S., KEHRWALD, D. Computa-tional study of pressure drop dependence on pleat shape and filter media. Filtech 2007 International Conference for Filtration and Separation Technology 2007, 1, 79-86. http://publica.fraunhofer.de/d....

55.

WRÓBLEWSKI, P., KOSZAŁKA, G. An experimental study on frictional losses of coated piston rings with sym-metric and asymmetric geometry. SAE International Journal of Engines. 2021, 14(6). https://doi.org/10.4271/03-14-....

56.

WRÓBLEWSKI, P. Technology for obtaining asymmetries of stereometric shapes of the sealing rings sliding surfaces for selected anti-wear coatings. SAE Technical Paper 2020-01-2229. 2020. https://doi.org/10.4271/2020-0....

57.

VOGEL, A., DURANT, A.J., CASSIANI, M. et al. Simula-tion of volcanic ash ingestion into a large aero engine: particle–fan interactions. ASME Journal of Turbomachinery. 2019, 141(1), 011010. https://doi.org/10.1038/srep25....

CITATIONS (2):

1.

Experimental Study of the Effect of Air Filter Pressure Drop on Internal Combustion Engine Performance

Tadeusz Dziubak, Mirosław Karczewski

Energies

Tadeusz Dziubak, Mirosław Karczewski

Energies

2.

Empirical study of the effect of the air filter on the performance and exhaust emissions of a diesel engine

Tadeusz Dziubak, Mirosław Karczewski, Ilona Dziobek

Combustion Engines

Tadeusz Dziubak, Mirosław Karczewski, Ilona Dziobek

Combustion Engines

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.