Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Response of hydrogen charging diffusion of the austenitic stainless steel AISI 310s

1

Mechanical, Wrocław University of Science and Technology, Poland

2

Mechanical, Wrocław University of Science and Technology, Poland, Poland

Submission date: 2023-07-11

Final revision date: 2024-02-18

Acceptance date: 2024-03-28

Online publication date: 2024-06-04

Publication date: 2024-08-09

Corresponding author

Małgorzata Julia Rutkowska-Gorczyca

Mechanical, Wrocław University of Science and Technology, Wybrzeże WYspiańsmiego, 50-370, Wrocław, Poland

Mechanical, Wrocław University of Science and Technology, Wybrzeże WYspiańsmiego, 50-370, Wrocław, Poland

Combustion Engines 2024,198(3), 68-73

KEYWORDS

TOPICS

ABSTRACT

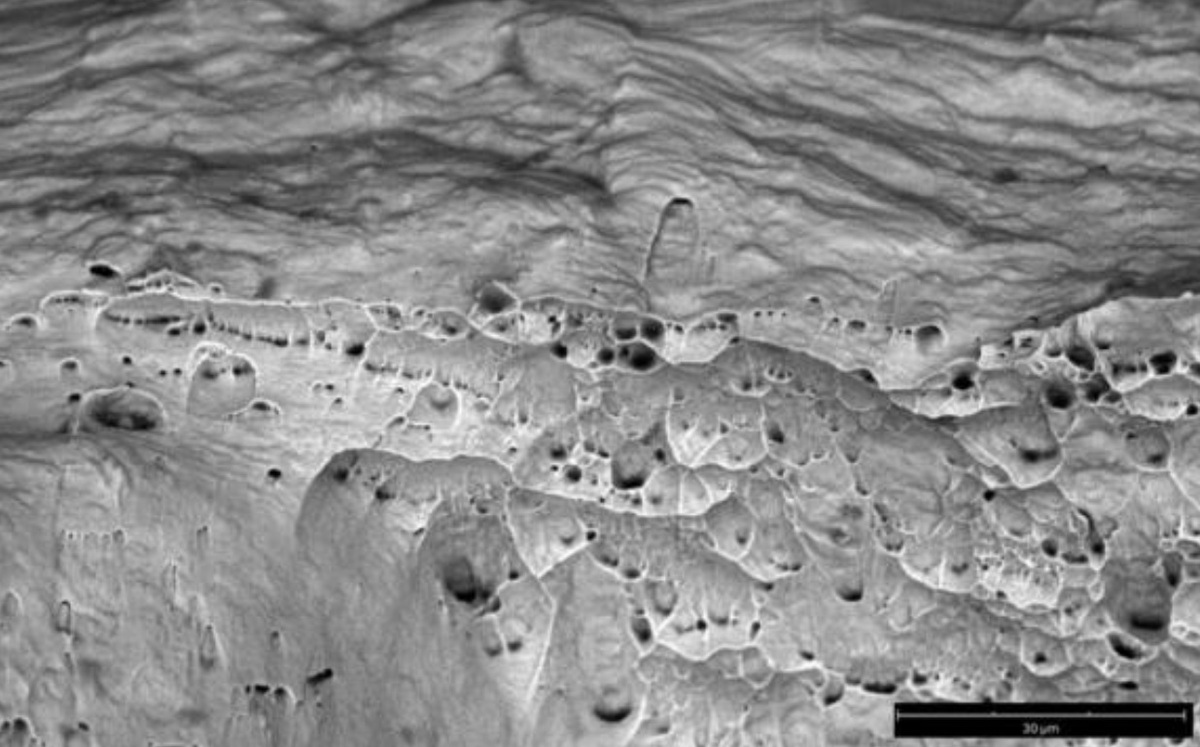

The subject of hydrogen embrittlement seems to be more and more up-to-date and needed to be explored. World research teams working on this issue have not developed a clear method of preventing this process. The conclusion is that this issue should be approached individually, depending on the type of material, its structure and operating conditions. The problem will escalate in the near future as a result of the planned replacement of the traditional energy sources used so far with hydrogen energy. The paper presents the method of electrochemical hydrogenation, which reflects the conditions of galvanic coating of metallic materials used in the automotive industry. The aim of the research was to determine the influence of the time of hydrogenation on the properties and microstructure of austenitic steel.

ACKNOWLEDGEMENTS

We would also like to thank PIK Instruments and Termo Fisher Scientific for providing the research equipment.

FUNDING

The work was carried out as part of a funding project from the National Science Centre Miniatura 6 with the number 2022/06/X/ST5/00729.

REFERENCES (28)

1.

Au M. Mechanical behavior and fractography of 304 stainless steel with high hydrogen concentration. No WSRC-TR-2002-00558 Savannah River Site (US). 2003;865. https://www.osti.gov/servlets/....

2.

Bertsch KM, Nagao A, Rankouhi B, Kuehl B, Thoma DJ. Hydrogen embrittlement of additively manufactured austenitic stainless steel 316 L. Corros Sci. 2021;192:109790. https://doi.org/10.1016/j.cors....

3.

Caskey GR. Fractography of hydrogen-embrittled stainless steel. Scripta Metallurgica. 1977;11(12):1077-1083. https://doi.org/10.1016/0036-9....

4.

Das T, Legrand E, Brahimi SV, Song J, Yue S. Evaluation of material susceptibility to hydrogen embrittlement (HE): an approach based on experimental and finite element (FE) analyses. Eng Fract Mech. 2020;224:106714. https://doi.org/10.1016/j.engf....

5.

Gavriljuk VG, Hänninen H, Tarasenko AV, Tereshchenko AS, Ullakko K. Phase transformations and relaxation phenomena caused by hydrogen in stable austenitic stainless steels. Acta Metallurgica et Materialia. 1995;43(2):559-568. https://doi.org/10.1002/978111....

6.

Hamaad ASAA, Tawfik M, Khattab S, Newir A. Device for using hydrogen gas as environmental friendly fuel for automotive engine (GREEN & ECO H2). Procedia Environ Sci. 2017;37:564-571. https://doi.org/10.1016/j.proe....

7.

Hatano M, Fujinami M, Arai K, Fujii H, Nagumo M. Hydrogen embrittlement of austenitic stainless steels revealed by deformation microstructures and strain-induced creation of vacancies. Acta Mater. 2014;67:342-353. https://doi.org/10.1016/j.acta....

8.

Khanchandani H, Gault B. Atomic scale understanding of the role of hydrogen and oxygen segregation in the embrittlement of grain boundaries in a twinning induced plasticity steel. Scr Mater. 2023;234:115593. https://doi.org/10.1016/j.scri....

9.

Kim HP, Park YM, Jang HM, Lim SY, Choi MJ, Kim SW et al. Early-stage M23C6 morphology at the phase boundary in type 304L austenitic stainless steel containing δ ferrite. Metals. 2022;12(11):1794. https://doi.org/10.3390/met121....

10.

Komatsu A, Fujinami M, Hatano M, Matsumoto K, Sugeoi M, Chiari L. Straining-temperature dependence of vacancy behavior in hydrogen-charged austenitic stainless steel 316L. Int J Hydrogen Energy. 2021;46(9):6960-6969. https://doi.org/10.1016/j.ijhy....

11.

Lai CL, Tsay LW, Chen C. Effect of microstructure on hydrogen embrittlement of various stainless steels. Materials Science and Engineering: A. 2013;584:14-20. https://doi.org/10.1016/j.msea....

12.

Lang F, Huang F, Yue J, Li L, Xu J, Liu J. Hydrogen trapping and hydrogen embrittlement (HE) susceptibility of X70 grade high-strength, acid-resistant, submarine pipeline steel with Mg treatment. Journal of Materials Research and Technology. 2023;24:623-638. https://doi.org/10.1016/J.JMRT....

13.

Li X, Ma X, Zhang J, Akiyama E, Wang Y, Song X. Review of hydrogen embrittlement in metals: hydrogen diffusion, hydrogen characterization, hydrogen embrittlement mechanism and prevention. Acta Metallurgica Sinica (English Letters). 2020;33:759-773. https://doi.org/10.1007/s40195....

14.

Longwic R, Tatarynow D, Kuszneruk M, Wozniak-Borawska G. Preliminary tests of a Diesel engine powered by diesel and hydrogen. Combustion Engines. 2023;195(4):35-39. https://doi.org/10.19206/CE-16....

15.

Mamala J, Graba M, Mitrovic J, Prażnowski K, Stasiak P. Analysis of speed limit and energy consumption in electric vehicles. Combustion Engines. 2023;195(4):83-89. https://doi.org/10.19206/CE-16....

16.

Matsuo T, Yamabe J, Matsuoka S. Effects of hydrogen on tensile properties and fracture surface morphologies of type 316L stainless steel. Int J Hydrogen Energy. 2014;39(7):3542-3551. https://doi.org/10.1016/j.ijhy....

17.

Nicho K, Yokoyama K. Marked degradation of tensile properties induced by plastic deformation after interactions between strain-induced martensite transformation and hydrogen for type 316L stainless steel. Metals. 2020;10(7):928. https://doi.org/10.3390/met100....

18.

Rieck RM, Atrens A, Smith IO. Stress corrosion cracking and hydrogen embrittlement of cold worked AISI type 304 austenitic stainless steel in mode I and mode III. Materials Science and Technology. 1986;2(10):1066-1073. https://doi.org/10.1179/mst.19....

19.

Saborío-González M, Rojas-Hernández I. Review: hydrogen embrittlement of metals and alloys in combustion engines. Revista Tecnología en Marcha. 2018;31(2). https://doi.org/10.18845/tm.v3....

20.

Safyari M, Khossossi N, Meisel T, Dey P, Prohaska T, Moshtaghi M. New insights into hydrogen trapping and embrittlement in high strength aluminum alloys. Corros Sci. 2023;223:111453. https://doi.org/10.1016/J.CORS....

21.

Tomaszewski S, Grygier D, Dziubek M. Assessment of engine valve materials. Combustion Engines. 2023;194(3):48-51. https://doi.org/10.19206/CE-16....

22.

Toribio J, Lorenzo M, Aguado L. Innovative design of residual stress and strain distributions for analyzing the hydrogen embrittlement phenomenon in metallic materials. Materials. 2022;15(24):9063. https://doi.org/10.3390/ma1524....

23.

Verhelst S, Wallner T. Hydrogen-fueled internal combustion engines. Progress in Energy and Combustion Science. 2009;35(6):490-527. https://doi.org/10.1016/j.pecs....

24.

Wang L, Fang X, Wang J, Zhang Z. The precipitation control of grain boundary M23C6 phases and the ductility improvement in aged 22Cr-25Ni-WCuNbN austenitic stainless steel by Co addition. Mater Lett. 2020;264:127348. https://doi.org/10.1016/j.matl....

25.

Wang Y, Wang X, Gong J, Shen L, Dong W. Hydrogen embrittlement of catholically hydrogen-precharged 304L austenitic stainless steel: effect of plastic pre-strain. Int J Hydrogen Energy. 2014;39(25):13909-13918. https://doi.org/10.1016/j.ijhy....

26.

Wu X, Zhang H, Yang M, Jia W, Qiu Y, Lan L. From the perspective of new technology of blending hydrogen into natural gas pipelines transmission: mechanism, experimental study, and suggestions for further work of hydrogen embrittlement in high-strength pipeline steels. Int J Hydrogen Energ. 2022;47(12):8071-8090. https://doi.org/10.1016/j.ijhy....

27.

Xue J, Wu H, Zhou C, Zhang Y, He M, Yan X et al. Effect of heat input on hydrogen embrittlement of TIG welded 304 austenitic stainless steel. Metals. 2022;12(11):1943. https://doi.org/10.3390/met121....

28.

Ye F, Zhu T, Mori K, Xu Q, Song Y, Wang Q et al. Effects of dislocations and hydrogen concentration on hydrogen embrittlement of austenitic 316 stainless steels. J Alloys Compd. 2021;876:160134. https://doi.org/10.1016/j.jall....

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.