Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Understanding technical cleanliness: importance, assessment, maintenance

1

Materials Testing, BOSMAL Automotive Research and Development Institute Ltd, Poland

Submission date: 2021-07-15

Final revision date: 2021-07-26

Acceptance date: 2021-07-26

Online publication date: 2021-07-27

Publication date: 2021-09-13

Corresponding author

Joanna FABER

Materials Testing, BOSMAL Automotive Research and Development Institute Ltd, Sarni Stok 93, 43-300, Bielsko-Biała, Poland

Materials Testing, BOSMAL Automotive Research and Development Institute Ltd, Sarni Stok 93, 43-300, Bielsko-Biała, Poland

Combustion Engines 2021,186(3), 41-50

KEYWORDS

TOPICS

ABSTRACT

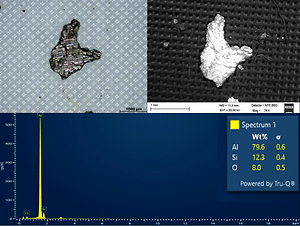

Development of the automotive industry, including so-called dowsizing and rightsizing, entails the need to ensure, and hence to verify, the stringent cleanliness levels of an increasing number of car components. The assurance of proper cleanliness level requires knowledge of the entire production process and precise information on the contaminants that will allow to identify their sources. Obtaining reliable cleanliness information requires establishing of many different factors, i. a. selection of proper contamination extraction and collection technique, proper parameters of extraction, validation of extraction procedure, methods of particles analysis. Analytical techniques which are implemented include gravimetric, optical microscopy and advanced techniques like scanning electron microscopy. This work present’s actual state of knowledge regarding technical cleanliness analysis of components. Important aspects of QA&QC in technical cleanliness assessment are also discussed.

REFERENCES (22)

1.

KOBLENZER, G. Trends in automotive parts cleaning. IST International Surface Technology. 2017, 10, 36-37. https://doi.org/10.1007/s35724....

2.

PEČMAN, J., LUPTAK, V. Cleanliness test for variable packing solutions in the automotive supply chain. The Archives of Automotive Engineering. 2021, 91, 49-62. https://doi.org/10.14669/AM.VO....

3.

International standard ISO 16232. Road vehicles – cleanliness of components and systems. 2018.

4.

VDA Automotive standard VDA 19.1. Inspection of Technical Cleanliness. Particulate Contamination of Functionally Relevant Automotive Components. 2015.

5.

DZETZIT, A., NAGIT, G. Research on importance of cleanliness in manufacturing reliable products for automotive. MATEC Web of Conferences. 2017, 112, 09017. https://doi.org/10.1051/matecc....

6.

STATHIS, A., KOULOCHERIS, D., COSTOPOULOS, T. et al. The impact of particle contaminants’ hardness on the wear mechanism of rolling element bearings. International Journal of Mechanical and Electrical Engineering. 2014, 1(1), 10-19.

7.

ORAVEC, M., DIVOKOVA, A., LIPOVSKY, P. et al. Technical cleanliness – a requirement of precision manufacturing. Acta Mechanica Slovaca. 2019, 23(4), 46-51. https://doi.org/10.21496/ams.2....

8.

FABER, J., BRODZIK, K. Elemental analysis as an important tool for fuels and biofuels quality control. Combustion Engines. 2017, 171(4), 140-144. https://doi.org/10.19206/CE-20....

9.

TUNG, S.C., TOTTEN, G.E. Automotive lubricants and testing. SAE International. 2012.

10.

FABER, J., SALA, R., KRASOWSKI, J. The influence of chlorine-contaminated fuel on NOx emission control elements in compression engine. Autobusy. 2018, 6, 414-420. https://doi.org/10.24136/atest....

11.

STĘPIEŃ, Z. The influence of particulate contamination in diesel fuel on the damage to fuel injection system. Combustion Engines. 2019, 177(2), 76-82. https://doi.org/10.19206/CE-20....

12.

STĘPIEŃ, Z., ŻÓŁTY, M. Examination of particulate contaminations contents in commercial diesel fuel. Tribologia – Finnish Journal of Tribology. 2020, 37(3-4), 37-44. https://doi.org/10.30678/fjt.9....

13.

LEE, J.-C., SHIN, H.-M. An experimental investigation on the contamination sensitivity of an automotive fuel pump. International Journal of Precision Engineering and Manufacturing. 2005, 6(3), 51-55.

14.

HYDAC International GmbH. Technical cleanliness: These days no longer an option, but an obligation. E 10.110.1.0/07.13.

15.

International standard ISO 14644-1, Cleanrooms and associated controlled environments – Part 1: Classification of air cleanliness by particle concentration. 2015.

16.

VW Standard PV 3347, Cleanliness of Engine Components. Determination of Residual Particle Quantities. 2019.

17.

BMW Standard QV 11 111, Appropriate Technical Cleanliness of Components and Fluids in BMW Power Train. 2020.

18.

Mercedes-Daimler Standard DBL 6516, Specification of Residual Dirt Limit Values. 2018.

19.

GM Standard GMW 16037, Test Method to Quantify Cleanliness of Engine and Transmission Components. 2017.

20.

Standard Volvo Group STD 107-0002, Contamination control. Cleanliness of components and systems. Test method. 2018.

21.

Scania specification STD4540, Specification and determination of technical cleanliness in media carrying systems. 2019.

22.

KOHLI R., MITTAL K.L., Developments in surface contamination and cleaning. Vol. 12: Methods for assessment and verification of cleanliness of surfaces and characterization of surface contaminants. Elsevier, Amsterdam 2019. https://doi.org/10.1016/C2017-....

CITATIONS (2):

1.

Occupational and Environmental Safety and Health IV

Catarina Pedrosa, N. Almeida, Fábio Pereira, C. Reis, Paula Braga

Catarina Pedrosa, N. Almeida, Fábio Pereira, C. Reis, Paula Braga

2.

LIBS as a fast and reliable alternative to µXRF and SEM–EDX for quantitative analysis of aluminium alloy particles in technical cleanliness analysis

Maria Lanzinger, Stephanie Kaufmann, Michael Schuster, Natalia P. Ivleva

Microchemical Journal

Maria Lanzinger, Stephanie Kaufmann, Michael Schuster, Natalia P. Ivleva

Microchemical Journal

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.