Current issue

Online first

Archive

About the Journal

Aims and scope

Publisher and Editorial

Advertising policy

For Authors

Paper review procedures

Procedures protecting authentic authorship of papers

Paper preparation manual

Plagiarism check

Publication ethics

Reviewers

APC

Editorial and Scientific Board

Contact

Reviewers

Waste-to-energy technologies as the future of internal combustion engines

1

Mechanical Engineering, Wroclaw University of Science and Technology, Poland

Submission date: 2023-01-13

Final revision date: 2023-02-14

Acceptance date: 2023-02-24

Online publication date: 2023-03-11

Publication date: 2023-06-14

Corresponding author

Mohamad Hamid

Mechanical Engineering, Wroclaw University of Science and Technology, wybrzeże Stanisława Wyspiańskiego 27, 50-370, Wrocław, Poland

Mechanical Engineering, Wroclaw University of Science and Technology, wybrzeże Stanisława Wyspiańskiego 27, 50-370, Wrocław, Poland

Combustion Engines 2023,193(2), 52-63

KEYWORDS

TOPICS

ABSTRACT

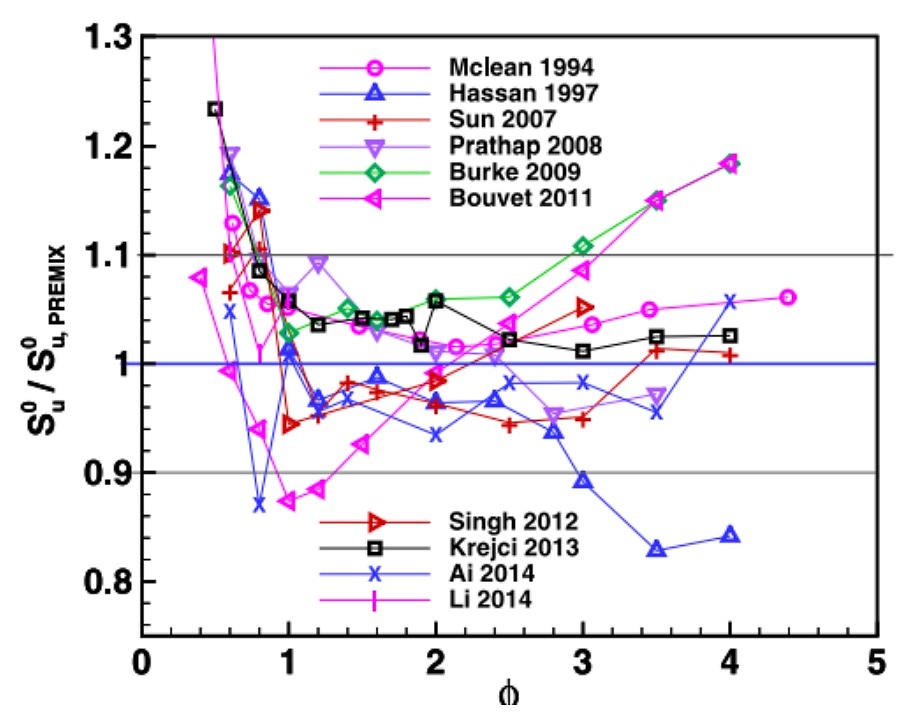

Syngas has a promising future as alternative to petroleum products and as a fuel for combustion engines. This study provides an overview on the feasibility of using syngas to power internal combustion engines. It presents technological process solutions for producing syngas toward minimizing the formation of tars as the most undesirable component for engine applications.. The combustion process characteristic of syngas composition has been tackled including critical criteria such as the flammability limit, ignition delay, laminar velocity, turbulent velocity, and the subsequent challenges in determining a numerical methods that best matches the exprimental datas. The syngas usage as alternative resource, while tackling the uncertainty issue of its composition, for Compression Ignition (CI) and Spark Ignition (SI) with the emission and performance effectiveness has been studied as well. The results of the review showed that syngas can be a viable alternative for some stationary applications, such as advanced integrated systems (ICCG), but its application is, however, relatively limited, for example as a secondary fuel in engines (CI) for automotive applications. However, significant discrepancies between numerical (simulation) and experimental results have been noted. This suggests that there are many scientific and experimental challenges in the area of syngas combustion processes in internal combustion engines. However, given the potential of this group of fuels, especially in the face of the energy crisis, this research is highly desirable and has a significant application perspective.

REFERENCES (48)

1.

Grzelak P, Żółtowski A. Environmental assessment of the exploitation of diesel engines powered by biofuels. Combustion Engines. 2020;180(1):31-35. https://doi.org/10.19206/CE-20....

2.

Sikarwar VS, Zhao M, Fennell PS, Shah N, Anthony EJ. Progress in biofuel production from gasification. Progress in Energy and Combustion Science. 2017;(61):189-248. https://doi.org/10.1016/j.pecs....

3.

Syngas & Derivatives Market: Global Industry Analysis (2022-2029) by Technology, Gasifier Type, Feedstock, Application and Region. https://www.maximizemarketrese....

4.

Ahmad AA, Zawawi NA, Kasim FH, Inayat A, Khasri A. Assessing the gasification performance of biomass: A review on biomass gasification process conditions, optimization and economic evaluation. Renew Sust Energ Rev. 2016;(53):1333-1347. https://doi.org/10.1016/j.rser....

5.

Gupta AK, Cichonski W. Ultra-high temperature steam gasification of biomass and solid wastes. Environ Eng Sci. 2007;24(8):1179-1189. https://doi.org/10.1089/ees.20....

6.

Basu P. Gasification Theory and Modeling of Gasifiers. Biomass Gasification Design Handbook. Elsevier; 2010.

7.

Aydin ES, Yucel O, Sadikoglu H. Numerical and experimental investigation of hydrogen-rich syngas production via biomass gasification. Int J Hydrogen Energ. 2018;43(2):1105-1115. https://doi.org/10.1016/j.ijhy....

8.

Basu P, Kaushal P. Modeling of pyrolysis and gasification of biomass in fluidized beds: A review. Chemical Product and Process Modeling. 2009;4(1). https://doi.org/10.2202/1934-2....

9.

Wang Q-D. An updated detailed reaction mechanism for syngas combustion. RSC Adv. 2014;4(9):4564-4585. https://doi.org/10.1039/C3RA45....

10.

Stępień Z. Synthetic automotive fuels. Combustion Engines. 2023;192(1):78-90. https://doi.org/10.19206/CE-15....

11.

Bielaczyc P, Woodburn J, Gandyk M. Trends in automotive emissions, fuels, lubricants, legislation and test methods – a global view, with a focus on the EU & US – summary of the 5th International Exhaust Emissions Symposium (IEES). Combustion Engines. 2016;166(3):76-82. https://doi.org/10.19206/CE-20....

12.

Mckendry P. Energy production from biomass (part 3): gasification technologies. Bioresource Technol. 2002;83(1):55-63. https://doi.org/10.1016/S0960-....

13.

Waldheim L. Gasification of waste for energy carriers : a review. IEA Bioenergy. 2018;(12). https://www.ieabioenergy.com/.

14.

Bosmans A, Wasan S, Helsen L. Waste-to-clean syngas: avoiding tar problems. 2nd International Enhanced Landfill Mining Symposium. 2013:181-201.

15.

Liu L, Zhang Z, Das S, Kawi S. Reforming of tar from biomass gasification in a hybrid catalysis-plasma system: A review. Appl Catal B-Environ. 2019;(250):250-272. https://doi.org/10.1016/j.apca....

16.

Bastos AK, Torres C, Mazumder A, de Lasa H. CO2 biomass fluidized gasification: thermodynamic and reactivity studies. Can. J. Chem. Eng. 2018;(96):2176-2184. https://doi.org/10.1002/cjce.2....

17.

Oveisi E, Sokhansanj S, Lau A, Lim J, Bi X, Preto F et al. Characterization of recycled wood chips, syngas yield, and tar formation in an industrial updraft gasifier. Environments. 2018;5(84):1-13. https://doi.org/10.3390/enviro....

18.

Tezer O, Karabag N, Ozturk MU, Ongen A, Ayol A. Comparison of green waste gasification performance in updraft and downdraft fixed bed gasifiers. Int J Hydrogen Energ. 2022;47(74):31864-31876. https://doi.org/10.1016/j.ijhy....

19.

Couto N, Rouboa A, Silva V, Monteiro E, Bouziane K. Influence of the biomass gasification processes on the final composition of syngas. Energy Proced. 2013;(36):596-606. https://doi.org/10.1016/j.egyp....

20.

Salem AM, Dhami HS, Paul MC. Syngas production and combined heat and power from scottish agricultural waste gasification – a computational study. Sustainability. 2022;14(3745). https://doi.org/10.3390/su1407....

21.

Nam H, Wang S, Sanjeev KC, Seo MW, Adhikari S, Shakya R, et al. Enriched hydrogen production over air and air-steam fluidized bed gasification in a bubbling fluidized bed reactor with CaO: Effects of biomass and bed material catalyst. Energy Convers Manag. 2020;(225):113408. https://doi.org/10.1016/j.enco....

22.

Kurkela E, Kurkela M, Tuomi S. Development of a bubbling circulating fluidized-bed reactor for biomass and waste gasification. Chem Eng Trans. 2022;(92):385-390. https://doi.org/10.3303/CET229....

23.

Meng J, Wang X, Zhao Z, Zheng A, Huang Z, Wei G et al. Highly abrasion resistant thermally fused olivine as in-situ catalysts for tar reduction in a circulating fluidized bed biomass gasifier. Bioresour Technol. 2018;(268):212-220. https://doi.org/10.1016/j.bior....

24.

Zhang W, Gou X, Kong W, Chen Z. Laminar flame speeds of lean high-hydrogen syngas at normal and elevated pressures. Fuel. 2016;(181):958-963. https://doi.org/10.1016/j.fuel....

25.

Lee HC, Jiang LY, Mohamad AA. A review on the laminar flame speed and ignition delay time of Syngas mixtures. Int J Hydrogen Energ. 2014;39(2):1105-1121. https://doi.org/10.1016/j.ijhy....

26.

Varghese RJ, Kumar S, Kolekar H. Effect of CO2 dilution on the burning velocity of equimolar syngas mixtures at elevated temperatures. 26th ICDERS, Boston 2017. http://www.icders.org/ICDERS20....

27.

Jithin E, Raghuram GKS, Keshavamurthy T v., Velamati RK, Prathap C, Varghese RJ. A review on fundamental combustion characteristics of syngas mixtures and feasibility in combustion devices. Renew Sust Energ Rev. 2021;(146):111178. https://doi.org/10.1016/j.rser....

28.

Varghese RJ, Kolekar H, Kumar S. Demarcation of reaction effects on laminar burning velocities of diluted syngas–air mixtures at elevated temperatures. Int J Chem Kinet. 2019;51(2):95-104. https://doi.org/10.1002/kin.21....

29.

Han W, Dai P, Gou X, Chen Z. A review of laminar flame speeds of hydrogen and syngas measured from propagating spherical flames. Applications in Energy and Combustion Science. 2020;1-4:100008. https://doi.org/10.1016/j.jaec....

30.

Chaos M, Dryer FL. Syngas combustion kinetics and applications. Combust Sci Technol. 2008;180(6):1053-1096. https://doi.org/10.1080/001022....

31.

Mathieu O, Kopp MM, Petersen EL. Shock-tube study of the ignition of multi-component syngas mixtures with and without ammonia impurities. P Combust Inst. 2013;34(2):3211-3218. https://doi.org/10.1016/j.proc....

32.

Samiran NA, Ng JH, Mohd Jaafar MN, Valera-Medina A, Chong CT. Swirl stability and emission characteristics of CO-enriched syngas/air flame in a premixed swirl burner. Process Saf Environ. 2017;112:315-326. https://doi.org/10.1016/j.psep....

33.

Zhao H, Wang J, Cai X, Dai H, Bian Z, Huang Z. Flame structure, turbulent burning velocity and its unified scaling for lean syngas/air turbulent expanding flames. Int J Hydrogen Energy. 2021;46(50):25699-25711. https://doi.org/10.1016/j.ijhy....

34.

Kim JS, Williams FA, Ronney PD. Diffusional-thermal instability of diffusion flames. J Fluid Mech. 1996;(327):273-301. https://doi.org/10.1017/S00221....

35.

Chen Z, Jiang Y. Numerical investigation of the effects of H2/CO/syngas additions on laminar pre-mixed combustion characteristics of NH3/air flame. Int J Hydrogen Energy. 2021;46(21):12016-12030. https://doi.org/10.1016/j.ijhy....

36.

Yang L, Weng W, Zhu Y, He Y, Wang Z, Li Z. Investigation of hydrogen content and dilution effect on syngas/air premixed turbulent flame using OH planar laser-induced fluorescence. Processes. 2021;9(11):1894. https://doi.org/10.3390/pr9111....

37.

Liu CC, Shy SS, Peng MW, Chiu CW, Dong YC. High-pressure burning velocities measurements for centrally-ignited premixed methane/air flames interacting with intense near-isotropic turbulence at constant Reynolds numbers. Combust Flame. 2012;159(8):2608-2619. https://doi.org/10.1016/j.comb....

38.

Chaudhuri S, Akkerman V, Law CK. Spectral formulation of turbulent flame speed with consideration of hydrodynamic instability. Phys Rev E Stat Nonlin Soft Matter Phys. 2011;84(2). https://doi.org/10.1103/PhysRe....

39.

Zhao H, Wang J, Cai X, Dai H, Huang Z. Turbulent burning velocity and its unified scaling of butanol isomers/air mixtures. Fuel. 2021;306:121738. https://doi.org/10.1016/j.fuel....

40.

He X, Zhou Y, Liu Z, Yang Q, Sjöberg M, Vuilleumier D, et al. Impact of coolant temperature on the combustion characteristics and emissions of a stratified-charge direct-injection spark-ignition engine fueled with E30. Fuel. 2022;309:121913. https://doi.org/10.1016/j.fuel....

41.

Gitano-Briggs HW, Kean KL. Genset optimization for biomass syngas operation. renewable energy – utilisation and system integration. InTech. 2016. https://doi.org/10.5772/62727.

42.

Puglia M, Morselli N, Pedrazzi S, Tartarini P, Allesina G, Muscio A. Specific and cumulative exhaust gas emissions in micro-scale generators fueled by syngas from biomass gasification. Sustainability. 2021;13(6):3312. https://doi.org/10.3390/su1306....

43.

Shah A, Srinivasan R, D. Filip To S, Columbus EP. Performance and emissions of a spark-ignited engine driven generator on biomass based syngas. Bioresour Technol. 2010;101(12):4656-4661. https://doi.org/10.1016/j.bior....

44.

Stolecka K, Rusin A. Analysis of hazards related to syngas production and transport. Renew Energy. 2020;146:2535-2555. https://doi.org/10.1016/j.rene....

45.

Guo H, Neill WS, Liko B. The combustion and emissions performance of a syngas-diesel dual fuel compression ignition engine. Proceedings of the ASME 2016 Internal Combustion Engine Division Fall Technical Conference. Greenville. October 9-12, 2016. https://doi.org/10.1115/ICEF20....

46.

Xu Z, Jia M, Li Y, Chang Y, Xu G, Xu L et al. Computational optimization of fuel supply, syngas composition, and intake conditions for a syngas/diesel RCCI engine. Fuel. 2018;234:120-134. https://doi.org/10.1016/j.fuel....

47.

Xu Z, Jia M, Xu G, Li Y, Zhao L, Xu L et al. Potential for reducing emissions in reactivity-controlled compression ignition engines by fueling syngas and diesel. Energy Fuels. 2018;32(3):3869-3882. https://doi.org/10.1021/acs.en....

48.

Bhaduri S, Contino F, Jeanmart H, Breuer E. The effects of biomass syngas composition, moisture, tar loading and operating conditions on the combustion of a tar-tolerant HCCI (Homogeneous Charge Compression Ignition) engine. Energy. 2015;87:289-302. https://doi.org/10.1016/j.ener....

CITATIONS (3):

1.

Conversion of a Spark-Ignition Gasoline Engine to Syngas: Assessment of Technical and Economic Indicators Based on Numerical Modeling

Leonid Plotnikov, Dmitry Krasilnikov, Danil Davydov, Alexander Ryzhkov

2023 Belarusian-Ural-Siberian Smart Energy Conference (BUSSEC)

Leonid Plotnikov, Dmitry Krasilnikov, Danil Davydov, Alexander Ryzhkov

2023 Belarusian-Ural-Siberian Smart Energy Conference (BUSSEC)

2.

Waste plastic pyrolysis oils as diesel fuel blending components: detailed analysis of combustion and emissions sensitivity to engine control parameters

Jacek Hunicz, Arkadiusz Rybak, Dariusz Szpica, Michal Geca, Paweł Woś, Liping Yang, Maciej Mikulski

Energy

Jacek Hunicz, Arkadiusz Rybak, Dariusz Szpica, Michal Geca, Paweł Woś, Liping Yang, Maciej Mikulski

Energy

3.

Assessing the Interplay between Waste-to-Energy Capacity, Infrastructure Investment, Technological Innovation, Composting Adoption, and Governmental Effectiveness

Mushab Rashid, Muhammad Khalid Anser, Abdelmohsen A. Nassani, Khalid M. Al-Aiban, Khalid Zaman, Mohamed Haffar

Energy

Mushab Rashid, Muhammad Khalid Anser, Abdelmohsen A. Nassani, Khalid M. Al-Aiban, Khalid Zaman, Mohamed Haffar

Energy

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.